Whether your company manufactures new equipment or repairs existing equipment, hose routing can sometimes pose a real challenge. With today’s Tier-4 engines consuming more space within engine compartments, routing a hose from point A to point B can be tougher than ever. If you’re lucky, you’ll find a way to snake a hose around multiple obstacles. If luck isn’t on your side, you’ll have to remove and replace components to route a hose. Even outside the engine compartment, as equipment designs become more compact, placing components within a smaller envelope also presents greater challenges.

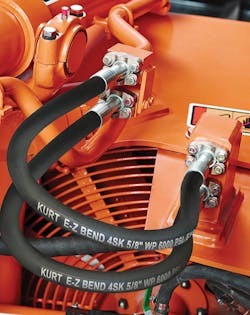

Fortunately, these challenges became a little easier with the introduction of E-Z Bend hose developed by Kurt Hydraulics, Minneapolis, Minn. E-Z Bend hose has half the bend radius of standard hose for easier routing. Providing greater flexibility and strength, E-Z Bend hose suits today’s compact applications that require hydraulic hose with tight bend radius using minimal installation force.

Targeted at high-pressure hydraulic oil lines in mobile and industrial hydraulic systems, E-Z Bend hose features four spiral layers of high-tensile-strength steel wire. Its inner tube is constructed of oil-resistant synthetic rubber. The hose’s working temperature range is –40 to 212°F, and it meets MSHA flame-resistance requirements.

E-Z bend comes in four standard sizes: â , ¾, 1 and 1¼ in. Working pressures range from 5,000 to 6,000 psi, and minimum burst pressures extend from 20,000 to 24,000 psi (both depend on hose size).

The hose is intended to be used with Kurt’s W-style end fittings, which come in 562 different types. Designed for use with SAE 100 R12 non-skive and all-wire-braided hose, the end fittings feature RoHS-compliant corrosion-resistant plating and are compatible with most model crimpers.

For more information or a free catalog, call (866) 257-7995 or visit www.kurthydraulics.com, where the catalog can be downloaded.