I found the answer to this and other questions during a recent visit to Life Formations, Bowling Green, Ohio, a company that makes animated and static characters for display and performances at trade shows, museums, amusement parks, commercial events, etc. After learning that the animated figures relied almost exclusively on pneumatic actuation, I expected to find some pretty run-of-the-mill mechanisms inside some not-so-ordinary exteriors. What I found were innovative designs and configurations of actuator assemblies operating in and under incredibly lifelike characters — human or otherwise.

Edison encounter

Shortly after I arrived at Life Formations for my first of two visits, technicians were working on Thomas Edison, who could be seen through an interior window in an electronic control room sitting in a chair. Except for his surroundings, he looked much like he does on our front cover, shown at right.

In a somewhat gravelly voice, Mr. Edison was speaking about the merits of soybeans. His incredibly real-looking eyes (which are actually human prosthetic eyes) scanned the control room, he gestured with his hands and arms, swiveled his chair, and even shifted in his seat as if uncomfortable.

After witnessing all this realism, it seemed bizarre when technicians removed a section of Edison’s scalp so they could adjust mechanisms inside the figure’s head. It seems there was a problem: Edison’s movements were sluggish. Cylinders acted slowly and did not fully retract or extend. All this made the figure’s motions appear out of synch with an audio tape producing the voice. After technicians checked virtually every component for leaks or malfunctions, a pressure regulator was found to be malfunctioning intermittently.

Tom Kuebler, vice president, art & design, explained that the Edison figure is rented to clients — in this case, an agricultural organization for a trade show. Kuebler works with clients on their script and how the Edison figure will present their message, then records the voice himself. Kuebler and programmers then use joystick controllers to generate 17 axes of motion in the figure to correspond with the audio tape. The joystick signals are recorded on a control tape, which goes though a series of edits until the program meets expectations. Other figures go through similar development, but are one-of-akind and sold rather than rented.

“Each figure we create is custom made,” explains Kuebler. “And although we start each project from scratch, certain techniques act as a starting point for any number of figures. Some companies, for instance, make an animated figure by trying to fit a sculpt around a robot framework that goes through the required motions. Our approach is to sculpt the figure, then design the mechanical and pneumatic systems into the sculpt.

What’s more, we can enhance the character to make the entire presentation more entertaining. Despite Mr. Edison’s brilliance and ingenuity as an inventor, he was not a dynamic speaker. His speech was very monotone and laborious. If he was speaking at a booth in a trade show, he probably wouldn’t draw much attention. When we recreate the Edison character for a presentation, we can make him speak and move as a polished professional.

“Potential clients sometimes ask to hear an authentic-sounding Edison. After we accommodate them, they always ask for a more polished look and sound. The voice usually ends up sounding something like Jimmy Stewart or Mason Adams.”

Pneumatic hardware

Life Formations makes extensive use of pneumatics for its longevity, reliability, and clean, quiet operation. For example, Tom Suter, vice president, administration, explains that “Eyeblinking mechanisms would seem to be ideal for actuation by electromechanical devices, such as solenoids. It’s a simple move with a short stroke. But we have found that electromechanicals don’t hold up as well as pneumatics. We also try to avoid servo control because it tends to add complexity and substantial cost to a system.”

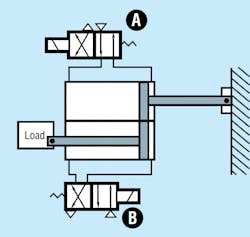

Instead of servo loops, Life Formations relies on mechanical design and unusual configurations to meet their needs. Figure 1 shows one such example: two cylinders mounted side-byside. This assembly has three design advantages:

- it essentially produces twice the stroke in the same longitudinal space as a single cylinder

- it provides a positive home (mid stroke) position with simple, open-loop control, and

- it provides two-speed operation.

With the load (head, torso, eyes, etc.) in, say, the left position, it can be moved to the right position by actuating cylinders sequentially. The load can also be moved from one extreme position to the other in half the time by actuating both cylinders simultaneously.

Unusual configurations such as this often result from meetings comprised of designers, artists, and mechanical technicians. The ideas that seem to defy convention often come about because a person “didn’t know any better” when attempting a non-traditional idea.

Sometimes, however, a controlled motion is required: acceleration, constant speed, deceleration. To achieve this, mechanical geometry is designed to produce harmonic motion. This makes changing a motion difficult once a figure has been made, but because these figures are unique, there is little likelihood that motions deviate from what can be changed by programming.

From a more conventional perspective, Doug Mollsen, technician, says, “We insist on clean air because we rely heavily on in-line flow restrictors to control speed of the movements. We can’t have components sticking or restrictors getting clogged from contaminants. Likewise, dry air keeps moisture from condensing in the systems.

“We’ve always known that pressure had to be carefully maintained. That’s why we can’t have any leaks. But pressure regulators never gave us problems before, that’s why it was the last thing we checked when Tom Edison wasn’t acting right. Pressure regulators have to repeatably provide the right pressure to keep motions synchronized with programs. If pressure wanders too high, some motions would execute too sharply. On the other hand, too low a pressure would cause sluggish movement and allow motions to lag behind command signals and prevent cylinders from fully extending or retracting.”

The blink of an eye

“Appearance is a high priority, but it isn’t everything,” explains Kuebler. For example, when making a character blink, speed is more important than visual details of the eyelid. “We could make eyelids for human figures out of a soft, pliable material like latex foam or silicone so that when the character’s eyes were closed, the eyelids would look strinkingly real. However, if we did this, blinks could not occur in a fraction of a second because the material would tear or quickly wear out.

“But real blinks don’t occur slowly,” continues Kuebler. “What we do is make an eyelid as a rigid cover that slides over, but doesn’t actually contact, the eyeball. If it remained closed, people could see that the eyelid was actually a smooth plastic cover instead of a detailed eyelid. But blinking eyelids don’t stay closed; they go from fully open to fully closed, and back to fully open in a split second. Obviously, this rapid movement doesn’t give an observer much time to scrutinize the authenticity of the eyelid. More importantly, the blink movement itself is authentic because it occurs as fast as an authentic blink instead of a slow, meticulous blink of a second or more.

Suter revealed that, “Eye blinks in movies are much more forgiving because the audience doesn’t necessarily see moves in real time. For movies, you can make an authentic-looking eyelid like Tom described and take two or even three seconds to execute a very precise blink. But when you print the film, you can run the blink at ten times its real-time speed, so you get the best of both worlds: absolutely authentic looks and speeds. We don’t have that luxury with live action.

“Movie producers can also get away with using a lot of cable mechanisms and puppet-type characters, which only have to perform for a short time,” continues Suter. “Who cares if a figure takes five guys to operate in unison? Once you get a good take, you’re done. Live-action animated figures, however, have to work on their own with little or no operator intervention.”

Compromise breeds success

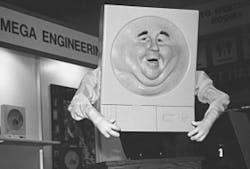

“Much of our success,” says Gene Poor, president, “is in making the right decisions for compromises. We pay close attention to the number and types of movements as they relate to the personality of a character. This means that more axes of motion isn’t always better. Jeeves the Butler (Figure 2) has one move: his mouth opens and closes. We could easily add more motions, but it isn’t necessary. He’s a very cold, impersonal butler who always looks straight ahead and talks and acts like he’s in a trance.

“We could make more sophisticated moves for other figures, such as puckering the lips when pronouncing an O or W. But this would add considerable cost to the figure and contribute little to realism. There are other ways of adding realism that are much more effective — and with little or no additional cost. It just takes some ingenuity.

“We think a big advantage we have is placing as much emphasis during design on the creative process as on the technology. In fact, we often don’t distinguish between the two because an artist may come up with an idea for doing something a certain way that hasn’t been done before. Technicians or engineers may not see this approach because they’re used to solving problems analytically instead of creatively.”

Poor adds that, “Some seemingly simple moves are actually quite complex, and, therefore, expensive to execute — like standing up from a sitting position or something as simple as a salute. These moves can be done, but to make them look natural reuires many carefully executed and synchronized motions and meticulous programming; otherwise, it will look like a machine standing up or saluting instead of a person. If a movement will look ineffective, we avoid it.”

Many times, realism is added by incorporating props into the figure. For example, instead of simply motioning with its hand while it talks, a figure might hold something — a pipe, pair of glasses, or some other personal effect — and go through gestures as it speaks. Kuebler points out that, “Posture is also important. If a figure will speak for awhile, it has to look comfortable by sitting down or leaning against a file cabinet instead of standing erect, like a robot would.”

“This gives the impression that we are visiting with the character while he or she was busy doing something else,” adds Suter. “The audience might expect Edison to get out of his chair and walk away when he’s done talking.”

Designing for realism

“Knowledge of human anatomy is essential to making lifelike figures with lifelike motions,” says Kuebler. “Cylinders become muscles. This doesn’t mean they have to be located in the same places as muscles, but they usually have to produce motion from the same places as a muscles. Sometimes this means running a cable or rod link from the cylinder to a frame member. In many cases, we locate cylinders that drive the eyes in the figure’s torso,” as shown in Figure 3. Cables run from the cylinders to the eye mechanism.

Many design techniques for placing cylinders in figures border on illusion. Perhaps the best example of this is a Louis Armstrong character, Figure 4, made for a museum that just opened in Chicago. The exhibit, called “Capone’s Chicago,” is located at 605 N. Clark St. in downtown Chicago; building facades on the entire block were modified to give a 1920s-era look. The character’s fingers appear to push down on the valves of a trumpet as he plays “Chicago. . . Chicago.” Kuebler reveals that, “the cylinders that generate the finger motion are actually in the trumpet valves, so the valves move by themselves and the fingers go along for the ride.”

A similar illusion is used for moving the head back. Normally, a cylinder in the torso would pivot a figure’s head back. Doing this was not practical for the Armstrong character because the cylinder would have to move the head, trumpet, and arms — quite a large mass mounted on a long moment arm. Instead, cylinders move the arms, which are connected to the trumpet, which is connected to the head. The head is mounted on a universal joint and follows the motion of the trumpet.

An important point is that these elements are not rigidly connected to each other. Ball-and-socket rod-end bearings are used extensively to allow individual elements to shift. And because body joints are anatomically correct, these reaction movements look natural, not stiff.

This illusion is repeated over and over. The Edison figure, for example, sits on a swiveling chair during its presentation. The chair turns left, then right as the character gestures and appears to scan and make eye contact with the audience as it speaks. Kuebler explains that, “People assume that his legs make the chair turn, because that’s what people do. Actually, actuators underneath the chair move it, and his legs simply follow this motion. It’s the same concept. Other movements make him shift in his seat. So after he’s been talking awhile, he begins to act uncomfortable, as anyone would.”

Animated industry

Companies capable of making sophisticated, lifelike animated figures traditionally have targeted theme parks as primary customers, according to Poor. “But figures like ours offer comparable realism at a cost of only 10% that of the flashy theme park ones. Because our figures are much more affordable, a whole new market has opened up for trade shows, museums, building lobbies, travelling attractions, and the like.”

Furthermore, Poor points out that audiences at theme parks represent a cross-section of the general population. At trade shows, museums, etc., members of the audience have something in common: they are there to learn about history, new products, new technologies, etc. This makes animating inanimate objects, such as furniture, light bulbs, or electronic instruments possible, because the audience will know what the animated object is.

Poor reveals, “We made a chart recorder that talks, sings, and even dances as part of a trade show exhibit for an instrument company (Figure 5). People attending the trade show certainly recognized that the figure was a chart recorder, but it spoke directly to them and entertained them — a form of infotainment. Another figure for the same company is an Einstein-like scientist that interacts with the chart recorder. “

Some of their clients were drawn to Life Formations by their own displays at shows. “We had a booth at a restaurant show, and except for a large crowd gathered around our booth, a hall the size of a football field was virtually void of attendees. Consequently, other exhibitors saw the attention we were getting and wanted us to do something similar for them,” says Poor.

For more information, call Life Formations at (419) 352-2101, email [email protected], or visit www.lifeformations.com.

Click here to choose from videos of projects completed by Life Formations, including a Colonel Sanders animated figure made for KFC and a bunch of Wacky & Whimsical Characters.

Click here to see static figures made for the Abraham Lincoln Presidential Library & Museum.