The pressure-containing envelope (barrel) of hydraulic cylinders and other metal fluid power components are made from a variety of ferrous and non-ferrous materials. In ferrous, the use of low-carbon 1026 steel (UNS G 10260) has been supplanted to a large extent by domestic equivalent grades to EN E355 or E460.

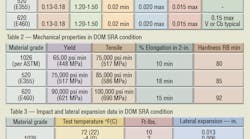

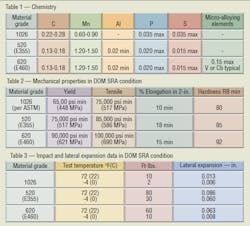

Chemical, mechanical, and impact properties of these three grades are shown in Tables 1, 2, and 3. The primary difference between the E355 and E460 grades is an addition of a micro-alloying element (up to 0.015% Vanadium or Columbium). These grades are generally available as drawn-over-mandrel (DOM) tubing, and to a lesser extent, cold-drawn seamless tubing. They are used in the manufacture of hydraulic and pneumatic cylinders, including single-and double-acting, ram, and telescopic cylinders with square head, bolted, and non-bolted construction.

The application of these grades to cylinder barrel manufacture came from a recognized need for higher toughness through improved impact properties reflective of environmental and functional considerations. Higher toughness improves resistance to damage from impact and other factors that may contribute to catastrophic failure over a range of temperatures.

Because E355 and E460 materials have a lower carbon content than 1026, they possess higher weldability while maintaining similar mechanical properties to 1026 grade. The comparisons were done in studies performed at the Edison Welding Institute, Mechanical Testing of Weld Joints in Hydraulic Cylinders. This study looked at the welding of 1026, TuffDOM 520 (E355) and TuffDOM 620 (E460) tubular samples and included Charpy V-notch impact and Crack Tip Opening Displacement (CTOD) tests to compare the relative performance of the TuffDOM grades to the existing industry standard 1026 grade (see tables).

The flat roll steel production of the TuffDOM grades requires careful processing controls during continuous casting and rolling. These processing requirements make raw material source selection an important criterion for the tubing mill and can limit the number of producers able to supply quality substrate. These grades are currently available from integrated and electric arc furnace steel mills that can consistently control elemental concentration, casting, and hot rolling practices for optimization of quality steel substrate for tubular production.

The Society of Automotive Engineers (SAE) has also recognized the need for high-pressure hydraulic assemblies to complement the cylinder performance. As a result, SAE 2613 and 2614 specifications were recently issued for use of micro-alloyed steel in ERW as-welded and DOM, in high-strength, annealed hydraulic tubing applications.

This information was submitted by Ed Vore, vice president, marketing and sales, Dofasco Copperweld, Shelby, Ohio. Contact him at (419) 342-1450 or visit dofascotube.com.