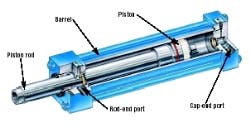

Fig. 1. Cut-away view shows key features of a typical cylinder, in this case, a doubleacting model for hydraulic service with standard tie-rod construction.

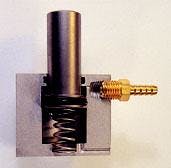

Fig. 2. Cut-away view shows key features of a single-acting cylinder. This partial model is base-mounted with an extension spring for a tool holding application.

Fig. 3. Telescoping cylinders have two or more stages that, when fully extended, can produce a stroke that exceeds the length of the cylinder when fully retracted. Shown here is a cutaway of a six-stage single-acting model.

The linear motion and high force produced by cylinders are big reasons why designers specify hydraulic and pneumatic systems in the first place. One of the most basic of fluid power components, cylinders have evolved into an almost endless array of configurations, sizes, and special designs. This versatility not only makes more-innovative designs possible, but makes many applications a reality that would not be practical or possible without cylinders.

Cylinder basics

The most common cylinder configuration is double acting, Figure 1. Routing pressurized fluid into the rod end of a double-acting cylinder causes the piston rod to retract. Conversely, routing pressurized fluid into the cap end causes the rod to extend. Simultaneously, fluid on the opposite side of the piston flows back into the hydraulic reservoir. (If air is the fluid medium, it usually is vented to the atmosphere.)

Because the area of the rod-end piston face is smaller than the cap-end area, extension force is greater than retraction force (assuming equal fluid pressures). Because total cylinder volume is less with the cylinder fully retracted (because of rod volume) than when the cylinder is fully extended, a cylinder retracts faster than it extends (assuming equal flow rates).

Single-acting cylinders, Figure 2, accept pressurized fluid on only one side of the piston; volume on the other side of the piston is vented to atmosphere or returns to tank. Depending on whether it is routed to the cap end or rod end, the pressurized fluid may extend or retract the cylinder, respectively. In either case, force generated by gravity or a spring returns the piston rod to its original state. A hydraulic jack for vehicles represents a common application of a single-acting, gravity-return cylinder.

Single-acting cylinders can be spring-extend or the more common spring-return type. A springextend cylinder is useful for toolholding fixtures because spring force can hold a workpiece indefinitely. The cylinder then releases the workpiece upon application of hydraulic pressure. Spring-applied/hydraulic-pressure-released (parking) brakes represent another common application of single-acting, spring-extend cylinders.

But the most common type of single-acting cylinder uses a return spring. In this version, pressurized fluid enters the cap end of the cylinder to extend the piston rod. When fluid is allowed to flow out of the cap end, the return spring exerts force on the piston rod to retract it. Factory automation — especially material handling — is a common application using pneumatic spring-return cylinders.

Standard constructions

Construction variations for single-and double-acting cylinders are based primarily on how the two end caps are attached to the barrel. Additional variations include wall thickness of the barrel and end caps, and materials of construction.

Tie-rod cylinders have square or rectangular end caps secured to each end of the barrel by rods that pass through holes in the corners of the end caps. Nuts threaded onto the end of each tie rod secure the end caps to the barrel. Static seals in the barrel/end-cap interface prevent leakage. A number of variations to this design exist, including use of more than four tie rods on a cylinder, or long bolts that thread into tapped holes in one of the end caps.

The majority of cylinders for industrial, heavy-duty applications use tie-rod construction and usually conform to National Fluid Power Association (NFPA) standards. These standards establish dimensional uniformity so cylinders from multiple manufacturers can be interchanged. However, care should be taken when interchanging cylinders because even though it conforms to NFPA dimensional standards, a cylinder may have proprietary features from its specific manufacturer that may not be available from a different manufacturer.

Welded cylinders have end flanges welded to the barrel and an end cap attached to each flange. End caps are secured in place by bolts that slip through holes in each end cap and thread into tapped holes in each end flange. This construction is lighter and more compact than the standard tie-rod configuration, which explains why welded cylinders find wide application in mobile equipment.

A variation to this construction has each end cap threaded into the end of the barrel. This construction, however, usually cannot accommodate as high a pressure rating as welded and can be more difficult to disassemble and reassemble.

Mill-duty cylinders have flanges welded to the ends of the cylinder barrels with end caps of the same diameter as the flanges. Bolts secure the end caps to the flanges. Their construction is similar to that of welded cylinders, but mill-duty cylinders have thicker barrel walls and heavier construction in general.

Large mill-duty cylinders often have a barrel wall thick enough for the end-cap bolts to be threaded directly into the barrel wall. As the name implies, these cylinders were originally designed for use in steel mills, foundries, and other severeduty applications.

Common variations

The most common type cylinder is the single-rod end, in which the rod is nearly as long as the cylinder barrel. The rod protrudes from the rod-end cap to transmit the generated force to the load. A double rod-end cylinder has a rod attached to both faces of the piston with each rod extending through a rod end cap. Double rod-end cylinders are useful for moving two loads simultaneously, and they also eliminate the differential area between the rod side and blank side of the piston. With equal areas (and cylinder volumes) on both sides of the piston, a given flow produces the same extension and retraction speeds.

Most telescoping cylinders, Figure 3, are single acting, although double-acting versions are available. Telescoping cylinders contain five or more sets of tubing, or stages, that nest inside one another. Each stage is equipped with seals and bearing surfaces to act as both a cylinder barrel and piston rod.

Available for extensions exceeding 15 ft, most are used on mobile applications where available mounting space is limited. The collapsed length of a telescoping cylinder can be as little as 1/5 its extended length, but the cost is several times that of a standard cylinder that can produce equivalent force. Models are available in which all stages extend simultaneously or where the largest stage extends first, followed by each successively smaller stage.

Cylinder life

An industrial cylinder should have a design factor of about 4:1 based on yield at rated system pressure. Many manufacturers of heavy-duty cylinders for mobile equipment specify a 3:1 design factor. A 15,000-psi stress at rated system pressure, with smooth system operation and no pressure pulses, is considered conservative. System pressure spikes that cause 30,000-psi stress often are not alarming, but at 30,000-psi unit stress, steel's dimensional change is 0.001 in./in. of length. For a 30-in. cylinder, a pressure spike of that intensity causes a length change of almost 1/32 in. Dimensional changes in stressed cylinders, or those subjected to wide temperature changes, may further limit allowable working pressures.

Large dimensional changes can seriously affect performance and life expectancy of nonmetallic cylinder seals. For example, extrusive failures of 80 Shore A durometer, synthetic Nitrile seals can occur when clearance exceeds 0.004 in. at fluid pressures over 3000 psi, or a 0.001-in. clearance with system pressure of 6000 psi. Such pressures can easily be reached in systems using differential cylinders or those with meter-out flow controls.

You must consider system shock pressures. If the hydraulic system contains speed control or energyabsorbing devices, pressure spikes can occur that are two to three times above normal system pressure. Therefore, determine the loading the cylinder will experience and then mount accordingly to maintain port seal integrity.