Time is money, but higher speed doesn't necessarily mean higher production — at least when it comes to industrial shredders for mixed materials. Because cars contain multiple materials — ferrous and non-ferrous metals, elastomers, and a variety of plastics — high-speed shredding could generate heat that would cause low-melting-temperature materials to gum up the works. On the other hand, having to rip through metals, tires, and other tough materials requires high torque — the ideal job for hydraulics.

To transmit low-speed, high-torque power for shredding, machines could use a gearbox to reduce speed and multiply torque from an electric motor. This often proves impractical, because the gearbox would be heavy and bulky, which would increase structural requirements. Also, shock loading often occurs when shredding blades suddenly encounter hardened steel.

Furthermore, materials often become wedged between shredding blades, making it necessary to quickly reverse direction of the blades to free the jam. Having to quickly and frequently reverse rotation would prove especially challenging for an electromechanical drive because of its high inertia.

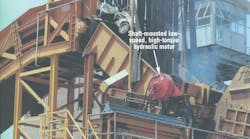

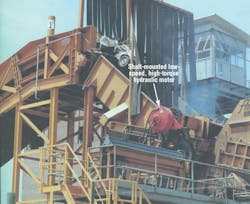

Hydraulic technology rises to the occasion by offering drive components that are much less bulky and more well-suited to the demands of high-torque shredding. For example, 60X85 Auto Shredders, from American Pulverizer Co., St. Louis, are driven directly by radialpiston motors from Hagglunds Drives Inc., Columbus, Ohio.

The motors can generate high torque from pressures as high as 5000 psi. Severe jam ups that could damage gear drives simply cause these motors to stall. Stall conditions increase pressure in the hydraulic system, which triggers valves to automatically reverse rotation of the drive to free the jam up.

One particular challenge of the application was mounting. The radial-piston motor produces high torque in an envelope that consumes relatively little axial space. Using flange-or foot-mounted motors would have required an extensive framework. Instead, the motor is mounted directly to the end of a shaft protruding from the shredding chamber. The motor is kept from rotating by a torque arm. This arrangement provides a compact, simple, and easy-to-install drive system.

For more information on Hagglunds low-speed, high-torque shaft mounted motors, call (614) 527-7401, or visit www.hagglunds.com