If a catastrophic failure causes a ship to lose its ability to maneuver, the vessel can be vulnerable to pounding waves and driving winds. Ultimately, the ship can break apart and leak fluids — causing environmental damage and racking up huge expenses for cleanup, repairs, and material losses. Marinvest AB, a fast-growing shipping company in Gothenburg, Sweden, realized the need for safer vessels, but was not content merely to meet current safety requirements. Marinvest has developed a low-speed, high-torque emergency drive system that can move a damaged vessel out of harm’s way should a major failure occur.

When Marinvest ordered four new vessels for its fleet, its safety and environmental standards were set higher than required by regulatory agencies and customers. This meant extra navigation equipment and extra protection for all oil tankers in order to increase safety for people and the environment. “We decided to install an emergency drive — a so-called take-me-home device,” says Roger Karlsson, technical director at Marinvest.

Efficiency in a small space

A Panamax-class vessel is relatively narrow (32.24 m), to facilitate passage through the Panama Canal. This means little space is available for an auxiliary drive. No feasible solution existed, so Marinvest decided to develop its own.

Various options were carefully explored — both traditional electromechanical emergency drive systems and drives using hydraulic motors, both combined with a gearbox. Gearboxes would require far too much room, but low-speed, high-torque hydraulic motors can transmit high power directly, with no need for gearboxes to reduce speed. Marinvest then turned to Hagglunds Drives, Mellansel, Sweden, for a solution capitalizing on the high power density of hydraulic drives.

Great experience

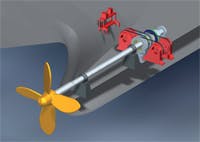

Hagglunds Drives accepted the technical challenge, relying on its experience with both simple and complex drive systems. Hgglunds’ drive system uses four compact motors. They attach to a foundation on the floor of the ship’s hull and drive a propeller shaft through strands of 312-in. pitch double roller chain.

The drive system is supplied with oil from an existing hydraulic system normally used to pump oil loads from tankers. The existing system has seven pumps and delivers to 2.6 MW of power at pressures to 270 bar. Each motor receives up to 1425 lpm, for a total maximum flow of 5700 lpm. Each motor rotates at 64 rpm and transmits up to 97,000 N-m of torque.

Takes little space

Karlsson is more than satisfied with the technical solution. “I’m honestly a little surprised at the elegant way we and Hagglunds have succeeded in designing the drive system,” says Karlsson. “We now have an emergency drive system that is efficient and takes little space.

“A major advantage of Hagglunds’ hydraulic drives is that we get a drive speed that suits the propeller characteristics. The drives have an output speed range that suits this type of vessel.” This brings up another advantage of hydraulics: speed regulation. If the ship has a variable-pitch propeller, propeller shaft speed needs to be regulated within a relatively narrow range.

However, the drive can also be used in ships using fixed pitch propellers. In this case, the hydraulic drive can vary its output speed to accommodate application needs, without having to run the engine at extreme high or low speeds. Karlsson adds, “The direct drive system takes up little space, as we don’t need a gearbox and the drive can easily be placed in an existing space.”

In port with good margins

Marinvest’s take-me-home drive using Hagglunds’ low-speed, high-torque motors gives vessels a speed of up to10 knots. “The capacity to do 7 knots is the requirement for approval as an emergency drive, but our drive exceeds that,” says Karlsson. The emergency drive has increased safety for the crew and the environment and has also opened up the possibility of Marinvest carrying out maintenance in port and selling the emergency-drive technology to others.

“Marinvest’s emergency drive system clearly shows that there are hardly any areas of use that are beyond the scope of compact, flexible, and powerful direct drive hydraulic systems,” says Lars-Gran Sderlund, a manager for marine and offshore at Hagglunds Drives.

Technical information for this article was provided by Patrik Ahlberg, of Hagglunds Drives, Lidkping, Sweden. For more information from Hgglunds Drives, visit www.hagglunds.com, or call (866) 509-2275 in the U. S.