Of particular interest were hydraulic lines running the length of the aircraft from large centralized pumps to actuators for brakes, landing gear, and the nose wheel steering system. Ordinarily, large commercial jets have three sets of redundant hydraulics: two primary circuits and a third back-up for safety.

To reduce this bulk, the all-hydraulic backup circuit was replaced with a decentralized hydraulicpower generation system. Signals from electronic control units (ECU) activate multiple small electrically- driven micropumps, each located close to the actuators they control. The micropumps provide 350 bar (5000 psi) of local hydraulic pressure over short runs of small-diameter, lightweight tubing for braking and steering, so it’s always available in an emergency.

A tall order for engineers

A world’s first in a commercial airliner, this Local Electrical Hydraulic Generation System (LEHGS) was developed by Messier-Bugatti, a subsidiary of the SAFRAN Group and a world leader in aircraft landing and steering systems. An Airbus partner for over 30 years, the company’s customers include 250 airlines, 20 military air forces, and major global aircraft manufacturers.

In optimizing system performance, project engineers faced challenges of integrating and sizing the many different physical parts, assemblies, and subsystems for the mechanical, electrical, and hydraulic systems. Moreover, they needed to assess any risk factors, such as electrical overloading.

Compounding the difficulty, tight deadlines and budgetary constraints prohibited numerous time-consuming and costly physical tests of system mock-ups. Instead, work in designing and optimizing the performance of this first-ever system would have to be done early in the plane’s development — before any hardware was built and at the same time other aircraft system designs were underway.

The solution: advanced predictive software

Messier-Bugatti met these challenges with the Imagine. Lab Ground Loads software based on the AMESim simulation platform, which the company had implemented on previous projects for predicting the behavior of complex multi-domain intelligent systems. Engineers began by selecting and piecing together individual components and subsystems from among a library of pre-defined items:

- hydraulic pressure drop,

- hydraulic component design,

- electromechanical, motors, and drives,

- thermal resistance,

- thermal hydraulics, and

- thermal, hydraulics, and electrical basics.

Unlike conventional system modeling languages that require computer programmers to write software, the overall system model is created graphically, and engineers are prompted to enter parameters where necessary. In this way, AMESim software creates a multi-domain system model from the overall conceptual information of interconnected parts and subsystems. Importantly, it does not require a full 3-D geometry representation, so engineers can simulate and predict the behavior of intelligent systems long before detailed CAD geometry becomes available.

Throughout this process, Messier- Bugatti system engineers took advantage of convenient access to Imagine. Lab Ground Loads software. The system’s flexible licensing arrangement enabled them to optimize the use of specific modules and libraries while lowering overall system simulation expenses.

Simulating complex behavior

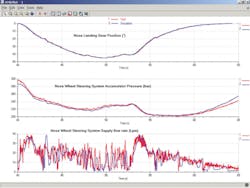

Ground Loads modeling and analysis capabilities allowed Messier-Bugatti to analyze behavior of hydraulic systems in terms of performance, stability, and robustness. Engineers also used the model to study the thermal characteristics of hydraulic circuits and evaluate the need for heat exchangers. These results were then used to establish the sizing, output, and other component specifications for the entire hydraulic power unit, including its reservoir, pump, and accumulator.

Using Ground Loads, engineers could also explore alternate sets of parameters and scenarios. When developing a steering system, for example, various combinations of components and systems (actuators, motors, valves, ECU, etc.) could be compared from specification to validation, thus significantly improving the steering system quality.

With these predictive capabilities, Messier-Bugatti simulated the behavior of the electrohydraulic system for the A380, validated system power-generating performance, and engineers accurately sized components early in development. This significantly reduced dependency on numerous physical prototypes. “Messier-Bugatti can use Imagine. Lab AMESim to tune complex multiphysics systems without performing a large set of tests on bench,” commented Michael Benmoussa, senior design engineer on the project.

Reducing guesswork

“Simulation enabled us to anticipate and reduce the inherent development risks of a new technology by incorporating an upstream validation regarding the technical choices,” continued Benmoussa. “Simulation results obtained in the early project stages using LMS Imagine.Lab AMESim were later confirmed on test benches with a very good accuracy.”

In this manner, Ground Loads can significantly reduce guesswork and free the engineering team to focus on innovation and R&D. “Messier-Bugatti was able to predict systems and equipment performances — including critical new technologies — on the entire flight domain,” commented Benmoussa. “The A380 enters into service with its nose wheel steering system control loop only tuned with LMS Imagine.Lab AMESim. Tests were performed to confirm the good system performance.”

For more information on AMESim and Imagine.Lab Ground Loads software from LMS Ltd., Troy, Mich., call (248) 952-5664, or visit www.lmsintl.com.