Cartridge valves can be described as control elements that require a housing, or manifold, to unlock their full potential. They can take many forms and offer a wide range of functions from the simple fixed orifice to the most advanced proportional directional and pressure controls.

The key to unlocking the functionality of these valves comes from the innovative circuits that hydraulic circuit designers create with hydraulic integrated circuits (HICs). HIC manifolds can be used to control one or more machine functions. Practical limits can occur in packaging, but it is not uncommon to see up to a dozen functions controlled by a single HIC.

Form

Industry standard threaded cavities provide a threaded interface to fasten the cartridge into a manifold. The thread form is similar to an SAE threaded interface with a spot face at the mounting surface and O-ring seals for leak-free operation. The cavity has multiple steps to accommodate a particular functionality. A simple check valve requires a one-step cavity with two flow passageways. The flow paths provide passageways to the nose and sides of the cartridge. Because the cartridge valve can provide flow 360° around the its body, designers can direct flow to or from multiple sources. A more complicated functionality — such as a directional valve with three positions and four flow paths — requires a cavity with three steps and four flow passageways. Flow patterns are specific to valve manufacturers and can vary as applications require.

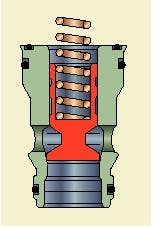

Slip-in valves are a relatively new form in HICs. The slip-in cartridge valve, Figure 1, was developed for use in low-pressure applications in power shift transmissions. The slip-in valve, as its name suggests, slips into the manifold and is retained with a clamping mechanism or plate that is secured on the face of the manifold.

The slip-in valve was developed to maximize the flow in a given size cartridge and typically has flow ratings equivalent to a threaded cartridge one size larger. Slip-in valves can offer lower costs when controlling pilot flows from joysticks and brake circuits. They are particularly appealing when assembling valves into complicated castings, because they create no contamination. State-of-the-art designs often incorporate slip-in valves into the hydraulic reservoirs of transmissions and engine oil pans.

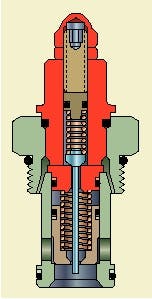

Logic elements are a form of pilot operated cartridge valve, Figure 2, that are used in much the same ways as DIN style cartridges. Logic elements are capable of high flow rates and can be manufactured to much larger frame sizes than typical threaded style cartridges. Logic elements rely upon pilot flow for control and can be used as flow control elements, relief valves, and directional controls.

When used in conjunction with proportionally varied signals, these elements can be used to create multi-stage valve controls. An increasingly popular variation on the logic element is an inserted element that is placed into a machined bore and retained in the manifold with a threaded or flanged cap.

Functionality

Cartridge valve manufacturers provide a wide variety of valve functions, allowing circuit designers to find almost any hydraulic control function in cartridge form. Typical functions provided by cartridge valves today include:

- check valves

- pilot-operated check valves (single-and dual-pilot operated)

- relief valves (both direct and pilot operated)

- sequence valves c pressure-reducing valves c flow control valves (pressureand non-pressure-compensated)

- load-control valves c counterbalance valves c flow-dividing/combining valves (fixed, priority, proportional divider)

- manual directional valves c solenoid valves in 2- or 3-way poppet or spool type, and 4-way, 2- or 3-position versions

- electro-proportional directional, flow, and pressure controls, and

- specialty valves: shuttle valves, velocity fuses, and composite material valves.

Innovations in cartridge valves have taken many paths in terms of functionality, size, and form. Manufacturers are incorporating multiple functionalities into single valves mixing flow, pressure, and directional controls to reduce the number of cartridges required to perform a given task. Additionally, internal valve leakage issues are being addressed with the use of engineered composites and other exotic materials.

Valves continue to grow both smaller and larger, as HICs are used to tackle lower flow applications and main system controls. Cartridge valves are being used in applications once thought to be purely the domain of sectional spool valves with capabilities beyond 50 gpm within reach. Miniaturization of valves for use in compact hydraulic packages has created valve solutions that are the thickness of a pencil and less than 1-in. long.

Pressure capabilities of cartridge valves continue to expand, as well. Demanding applications in the mobile market are pushing working pressures to 6000 psi (415 bar) with intermittent demands of up to 7200 psi (496 bar) in some cases. Cartridge valves capable of operating in these conditions and beyond are being developed and produced in many styles.

Advancements in cartridge design also come from practical areas, as machine users place equipment in more demanding environments. Some of the most important gains in machine reliability have come from improved resistance to moisture in electrical solenoids. Users — particularly in the growing rental markets — frequently wash down equipment with high pressure washers. Solenoids with molded connectors and weather resistant molding techniques offer IP69 ratings for maximum protection.

New materials, new possibilities

Materials advancements and the use of multi-axis CNC controlled machines have given designers more options when designing HIC solutions. Manifolds once made almost exclusively from cut bar stock or extruded aluminum are now manufactured from advanced steels and aircraft quality alloys. Availability of lower cost tooling has made complex cast shapes economical in volumes much lower than in days past. The use of extruded steel shapes has provided designers a more economical starting ground for systems that exceed 3000 psi (206 bar). The improved quality of aluminum alloys is allowing properly designed aluminum HICs to operate in excess of 3600 psi (250 bar) in many cases.

Cast shapes in iron and aluminum provide packaging advantages in some machines. Integration of circuits into cylinders, pump housings and machine elements can take advantage of valuable machine real estate and reduce potential leak paths. Long term cost advantages can be real-ized, due to reduced machining costs of cavities and flow paths. Castings allow valves to be packaged in many different planes with complex geometries in the inner coring.

Advancements in CNC machining and CAD packages have opened up additional opportunities in system packaging. Multi-axis CNC centers can machine flow paths at odd angles and provide precision cavities for inserted elements. CAD packages with cavity libraries allow designers to place valves and populate manifolds with flow paths automatically. Error checking algorithms allow the designers to ensure that oil is delivered where it is required with minimal pressure drops. CAM packages help manufacturers move these designs from the CAD workstation to the machine with automatically generated CNC programs allowing rapid prototyping and seamless transitions into production.

System advantages of HICs

Packaging — Light weight and compact size are the genesis of the cartridge valve industry. HICs are frequently 1 /4 to 1 /3 the size and weight of individually plumbed valve packages. Extensive use of lightweight materials can save up to an additional third in weight reduction over traditional valve solutions. These weight and packaging advantages can increase vehicle efficiency and offer manufacturers additional vehicle capacity.

Performance — Elimination of hoses, fittings, and external plumbing can reduce system pressure drops, eliminate leak points, and optimize vehicle performance. Components are closely packaged and runs between control elements, a source of heat generation, are reduced providing more usable power to the application. Proportional control valves are provided with optimal flow conditions, making the full performance range of the valve available. Additionally, HICs are routinely used at pressures up to 6000 psi (415 bar) — often double that of traditional cast iron valves.

Costs — Incorporating many of a machine's control features in a single HIC can eliminate multiple hose runs, interconnections between components and the associated assembly times. An HIC solution incorporates pilot lines, load sense, drains, and other features that would otherwise be plumbed on a machine. The elimination of connections and external plumbing can often result in savings of 40 to 50% over traditional solutions. Efficiencies in manufacturing and compact packages can offer additional savings while offering a custom fit control solution.

Reliability — HICs can offer increased reliability to an manufacturer. The previously mentioned plumbing improvements make the machine less susceptible to vibration-related downtime. Additionally, fatigue is less of a factor due to lighter weight and improved mounting configurations. HICs that are integrated into other machine components can further increase machine reliability with their optimized mounting configurations.

Serviceability — Increased machine life-cycles requires that servicing of components be easy and risk free. The inherent ease of application of cartridge valves makes for convenient servicing and repair. End users can make repairs in the field without breaking hydraulic hose connections which can potentially lead to spilled oil, contamination, and improper hose routings. The manufacturer can be assured that a used piece of equipment repaired in the field will operate properly and be up and running in a minimal amount of time. Additional benefits can be derived from clear labeling of valves in the manifold, as shown at right. A repair technician can refer to call outs that will not fall off or become illegible over time.

Manufacturability — HICs can be custom configured to route hoses and fittings for ease of assembly. Many manufacturers will have the HIC designed to place all of the hydraulic connections on a common face, allowing easy access to both valves and fittings. Because of their compact nature, HIC manufacturers can use innovative mounting options allowing control packages to be mounted to doors or access panels. The panels may swing out, allowing the assembler (and re-pair technician) easy access to the hydraulics. Integration of HICs with cylinders, motors, and pumps may allow manufacturers to reduce the number of components to be assembled into a machine further reducing assembly times as well as shaving transactional costs.