The Old Timer of Royal Oak, Mich., was a regular contributor to H&P years before we ever even heard of the internet. But most of his advice is just as ueful — and interesting — today.

So rather than leave his wisdom printed on pages archived in our storage room, I pulled out issues from the late 1980s and early 1990s and will reproduce relevant entries in this blog. Here is my sixth entry, which was originally published in the December 1987 issue:

Rube Goldberg would have loved this one

In one of the far corners of our facility, a pusher cylinder moved scrap bales up an inclined conveyer to an opening in the wall. There, three selector cylinders chose paths in an outside distribution chute arrangement to load the bales by gravity into railroad cars. All cylinders were air-operated. The system worked well most of the time, but the pusher cylinder was a little under-powered for some of the bigger bales, and in sub-zero weather, the outside cylinders sometimes froze up.

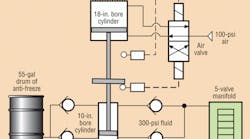

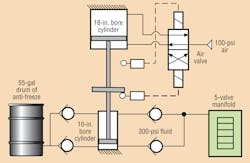

Sifting through our Junk Dept., we uncovered two oil air/oil cylinders (one with 10-in bore, the other with 18-in; both with a 2-ft stroke) a box of hydraulic check valves that appeared serviceable, and a manifold with five pre-piped, solenoid-actuated 4-way valves.

I had just winterized my car, so I was inspired to create — with this mixed bag of components and some help from the frame shop and welding gang — an air/anti-freeze intensifying hydraulic system. We slapped it together in two days using a 55-gal drum for the reservoir.

With 100-psi supply air, the 18-in cylinder stroked the 10-in cylinder to raise the pressure in our anti-freeze reciprocating pump circuit to 300 psi. Our fluid stayed liquid down to –30°F, and we even had a spare 4-way valve available when we needed it.

We had one unforeseen problem with this set-up. A few misguided souls were tempted to siphon off a little fluid for their cars. We added some bright red dye to the anti-freeze and we let the word slip out that this “new fluid” would destroy radiator cores. That stopped the pilferage, and the dye sure made it easy to find leaks.