A question I'm asked regularly is: "What is the best way to test the integrity of the piston seal in a double-acting hydraulic cylinder?"

There is a simple bench-test for doing this but it involves the intensification of pressure in the cylinder. While the test procedure is safe if you understand the concept of intensification in a hydraulic cylinder - it is inherently dangerous if you don't. In this post I will explain the dangers of intensification in a double-acting cylinder and in my next post I will explain the test procedure.

Force produced by a hydraulic cylinder is a product of pressure and area (F = p x A). In a conventional double-acting cylinder the effective area and therefore force produced by the piston and rod sides of the cylinder are unequal. It follows that if the rod side of the cylinder has half the effective area of the piston side, it will produce half the force of the piston side for the same amount of pressure.

The equation F = p x A can be transposed as p = F/A that is, pressure equals force divided by area. If the rod side of the cylinder has to resist the force developed by the piston side, with only half the area, then it needs double the pressure. This means that if the piston side is pressurized to 3,000 PSI a pressure of 6,000 PSI will be required on the rod side to produce an equal force. This is why pressure intensification can occur in a double-acting cylinder. Note that pressurizing a cylinder rated at 3,000 PSI, to 6,000 PSI, can have devastating consequences. Watch this 6-minute video for a better understanding of pressure intensification in a hydraulic cylinder.

If, for any reason, the piston side of a double-acting cylinder is pressurized and at the same time fluid is prevented from escaping from the rod side, pressure will increase (intensify) in the rod side of the cylinder until the forces become balanced or the cylinder fails catastrophically. Consider the following scenario one of our members described to me recently:

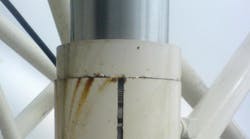

"It was minus 36 degrees here the other day and we had a hydraulic cylinder at about minus 10 degrees. The boss was attempting to press out a pin. He turned on the pump and moved the lever. Next thing, the gland of the cylinder blew out. It was a 7.5" cylinder with a 2,500 PSI operating pressure."

The gland on this hydraulic cylinder blew out as a result of pressure intensification. This was due to a blockage between the rod side of the cylinder and tank, as a result of the cold conditions. The ambient temperature had fallen below the pour point of the hydraulic oil, so the oil couldn't flow.

As you can see, pressure intensification in a double-acting hydraulic cylinder is a potentially dangerous phenomenon. And failing to consider its implications can be a costly mistake. To discover six other costly mistakes you want to be sure to avoid with your hydraulic equipment, get "Six Costly Mistakes Most Hydraulics Users Make... And How You Can Avoid Them!" available for FREE download here.

Continue Reading

Continue Reading

BOOK 2, CHAPTER 12: Fluid Motor Circuits

March 18, 2009

Motor leakage variations

Oct. 18, 2006

Sponsored Recommendations

Sponsored Recommendations

All-In-One DC-UPS Power Solutions

March 13, 2024

Motor Disconnect Switches

March 13, 2024

Industrial Straight-Through Cable Gland

March 13, 2024