Bosch Rexroth’s ML-18 pressure-compensated load-sensing control valves may take energy efficiency to the next level. The ML-18 design was developed to reduce power consumption on new Tier 4 applications, such as skid steers, small wheel loaders, and material handlers. In applications requiring up to

40 gpm (151 lpm) at 4,000 psi (276 bar), the ML-18 can reduce pressure drops as much as 50% versus the traditional valves, therefore reducing hydraulic power consumption for small machines

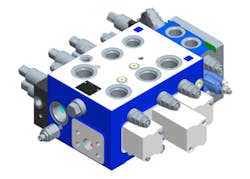

Key features of the valve that enable such savings are the monoblock design, which reduces interface restrictions between sections, dedicated tank coring for the highest flow section, and the use of backpressure valves for forced-flow regeneration. To achieve these features, Rexroth employed computer modeling to optimize the internal flow passages improving flow geometry while simultaneously minimizing the overall package size.

The ML-18 architecture was developed to give OEMs a choice between electrohydraulic and pilot operation for spool modulation. Doing so gives the ML-18 the flexibility to meet the control system of choice depending on application requirements. Although the base configuration for the ML-18 is a three-spool monoblock design, it was developed so that the Rexroth M4-15 Series sectional valves could be added to the end of the monoblock to provide the flexibility to optimize configurations.

For more information on the ML-18 valve, visit www.boschrexroth-us.com.