Pressure dew point is a normally used to indicate the amount of moisture air contains at line pressure. Pressure dew point is the temperature below which moisture will condense out of compressed air. For example, if a compressed air system has a pressure dew point of 45°F, moisture in the air will not condense as long as the air temperature remains above 45°F. If the temperature drops to 40°F, however, moisture in the air will condense, and liquid water will appear in the system, potentially damaging tools, components, and downstream processes

The bottlers of Perrier mineral water manufacture their distinctive-looking bottles by blowing molten glass into molds. Each molding machine produces bottles for 24 hours a day, every day of the year — making production equipment reliability and integrity of utmost importance.

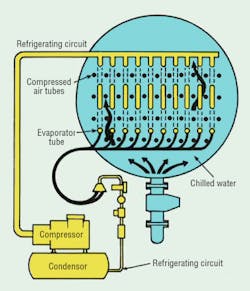

The air drying system includes five heat exchangers. Two air-to-air units substantially lower the moisture content of the wet air. An air-to-water heat exchanger, located between the two air-to-air heat exchangers, then cools the compressed air. A refrigerant-type water-chiller cools the recirculating water. Finally, a second air-to-water heat exchanger regulates the temperature within ±1°F. All components are mounted on a common frame. Two of these installations are now operating at Perrier.

The chiller in the refrigeration drying system consists of a refrigeration evaporator and compressed air tubes. Chilled water flows between the two sets of tube bundles to achieve two objectives: tact as a heat exchanger between the evaporator and the compressed air, and to provide a constant source of cold storage

Chilled water temperature is held at 32°F. When water temperature rises, the refrigeration compressor starts up; when water temperature drops, the refrigeration compressor stops after a thin layer of ice has coated the evaporator tubes. The thermal inertia of the chilled water is increased by that of the ice — making it 80 times greater. Thus, the efficiency of the air dryer is the same as that of the refrigeration compressor, whether or not it is operating.