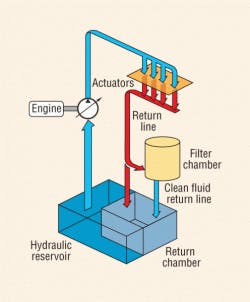

Keeping oil clean is essential for the reliable operation of any hydraulic system. But clean oil is especially challenging for construction equipment, where it is constantly exposed to dirt, water, and infrequent maintenance. Designers at LBX Co., (makers of Link-Belt earthmoving, forestry, and material handling equipment), Lexington, Ky., decided to meet all these challenges head on with their Nephron filtration system.

The Nephron system diverts about 3% of the hydraulic system’s return flow into its Nephron filtration chamber to eliminate contaminants 1 µm and larger. Nephron’s multi-layered filter element significantly reduces hydraulic system breakdown and maintenance costs under normal usage. Less wear and tear on the hydraulic components means more years of reliable performance.

Another advantage of the Nephron system is that hydraulic fluid only needs to be changed after every 5,000 hr of operation, as opposed to every 2,000 hr for other excavators. This results in a significant cost savings, both in servicing costs and machine downtime. In addition, cleaner oil results in longer life for hydraulic components. The environment wins, too: less frequent oil changes means a reduction in waste contaminants.

Return lines also incorporate an oil cooler to prevent high temperatures that otherwise would degrade hydraulic fluid from oxidation. LBX also provides a swing-out oil cooler to make it easier to clean both the cooler and the machine’s radiator. Other helpful features include extra-wide access doors, centralized lubrication banks on attachments, a hydraulic reservoir breather cap, and sealed automotive-style wiring harnesses. Making the equipment easier to maintain makes it more likely it will be.