To avoid severe vibration and premature failures, rail and truck shipping containers are subjected to vibration testing. However, failures often occurred because testing was originally only done on the X, Y and Z axes. Studies indicated that the pitch, roll and yaw axes simultaneously exert significant forces that can cause premature product efficiencies, normally attributed to design deficiencies.

To alleviate these failures, J.E. Myles Inc., a hydraulic systems distributor in Troy, Mich., worked with our sister company, Control Power-Reliance, to engineer the world’s largest six-axis transportation simulator in 1996. The testing system simulates rail and truck routes used in transporting containers in six axes using time history field data. This increases the realism of the test and provides high correlation to real world failures.

The system included six high-speed servovalves that run up to 50 Hz. The simulator features a motion base with six electrohydraulic axes. The hydraulic power unit controlling the cylinders is sized at 500 gpm and rated for pressures to 3000 psi.

Sticking with the original fluid

The simulator was designed to run five to six days per week, two shifts per day. And despite this almost constant operation, the simulator continues to run using the original hydraulic oil today.

We needed a 1000+ gal reservoir and a cooling system to keep the oil temperature at 110°F or less. The simulator’s continuous operation was crucial — downtime had to be kept to an absolute minimum. With this in mind, the distributor specified that Parker KleenVents be installed on the reservoir to keep the hydraulic oil clean.

Even in the most sterile environments, constant air flow through the reservoir can raise the total acid number (TAN) of hydraulic oil, slowly degrading its properties and causing oxidation of the fluid. This, in turn, can lead to varnishing of system components and premature wear. Or both. In fact, air is one of the most detrimental hydraulic system contaminants. Moisture in the air containing contaminants can condense inside reservoirs and fall into the oil as water. High ambient and operating temperatures only serve to accelerate acidic build-up.

When the TAN exceeds a predetermined level, critical machines must be shut down, the oil drained and disposed of, and new oil purchased — a time-consuming and costly proposition that scheduled maintenance alone cannot prevent.

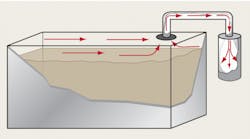

The KleenVent KV Series reservoir isolator helps to ensure continuous equipment operation. KleenVents use an elastomeric bladder as a ‘lung,’ where changes in gas volume in the reservoir can be contained and prevented from mixing with the outside air.

In operation, when the hydraulic reservoir is filled, the air on top of the oil goes into the KleenVent bladder. When the oil level in the reservoir goes down, the bladder pushes air back into the reservoir. This containment approach completely eliminates the potential of pulling in outside air. The atmosphere acts against the outside of the bladder isolator, while internally the same air is continuously exchanged between the reservoir and the bladder.

This separation allows the system to operate normally, while preventing ingestion of airborne contaminants. Unlike conventional breather-vent filters, Parker’s reservoir isolator provides positive separation without clogging, making it maintenance-free. With proper bladder material selection, KleenVents are compatible with virtually any type of hydraulic fluid.

Benefits abound

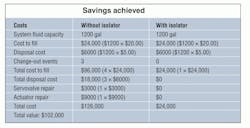

The J.E. Myles/Control Power-Reliance transportation simulator was put into operation in July 1996. At that time, the TAN of more than 1000 gal of hydraulic oil was 0.75. As of March 2011 — after 177 months and more than 620,000 hr of operation — the simulator continues to run using the original hydraulic oil.

The system has never experienced a servovalve or actuator failure — again partly attributable to consistently outstanding fluid cleanliness levels. It is estimated that it could cost between $1000 and $5000 to repair one of the simulator’s six 250-gpm servovalves, while repair of a 12-in. bore × 8-in. stroke, single 50,000 in.-lb actuator, — of which there are also six — would range from $3000 up to $15,000.

If it was not for the Parker KleenVents, we would have likely repaired at least one servovalve and actuator to this point.

By using KleenVent reservoir isolators, we have kept the simulator system free of airborne contamination and moisture that is usually introduced through a standard filler breather. As a result, filters are only needed to remove wear-generated particles, while varnishing of the servovalves has been non-existent.

The cost savings in hydraulic fluid, meantime, has been remarkable. Assuming an average cost of $18/gal for new oil, and an average disposal cost of $4.50/gal for old oil, the KleenVent solution has saved us more than $90,000 since 1996.

Besides the cleanliness of the oil and the money saved, the greatest benefit has been the uninterrupted system function we can count on every day.

For information, contact the author at (248) 583-1020, email [email protected] or visit www.cp-r.com. Visit bit.ly/hp1212kleenvent for more details on Parker’s KleenVents.