Constant progress is part of life. We may rail against it at times. But we can’t stop it. And it manifests itself in many different ways.

In engineering, we’ve grown accustomed to machines and their component parts becoming stronger, lighter, cheaper, smaller, more powerful, and more efficient. Nowhere is this more evident than in the field of information technology. In fact, according to Moore’s Law — named after Gordon Moore, cofounder of Intel Corp. — the power of computer chips doubles every 18 months. At the same time, the cost of this extra computing power to the consumer decreases exponentially.

But as consumer cost of computing power falls, the cost for manufacturers to fulfil Moore’s law heads in the opposite direction: R&D, manufacturing, and testing costs have steadily increased with each new generation of chips.

This has led to the definition of “Moore’s Second Law,” which states that the capital cost of semiconductor fabrication increases exponentially over time. This means progress comes at a cost — somewhere along the supply chain, at least.

Advances in hydraulics

The rapid and constant development we’ve seen in the IT sector is a hard act to follow. But like most other areas of mechanical engineering, the hydraulics niche hasn’t been resting on its laurels either.

Component operating pressures have increased steadily over the past 30 years, and this trend is forecast to continue. Seal and hose design has improved accordingly, as has oil additive and filtration technology. Advances in materials and manufacturing techniques mean more efficient hydraulic components with higher power densities are available at lower cost.

In short, much progress has been made—most of it good. But it has come at a cost. Higher operating pressures and closer tolerances make the hydraulic machine more susceptible to wear and damage resulting from oil contamination and inadequate lubrication. This means proactive maintenance is essential for optimum reliability and performance of today’s hydraulic equipment.

But just as Moore’s Law is expected to hold true for another generation, so will the pursuit of performance gains by hydraulic equipment manufacturers. The question is: where to from here? In answer to this question, I believe some hydraulic equipment manufacturers are headed in the wrong direction. They are “dancing with the devil,” so to speak. I hope my use of this metaphor will make sense once I explain.

A colleague who works for a major hydraulic component manufacturer recently told me his company’s original equipment manufacturer (OEM) customers are demanding components that can handle hydraulic system operating temperatures in excess of 110°C. And this number is not for margin of safety — it’s for continuous operation. But heat is the biggest enemy of a hydraulic system — more so than particle and water contamination these days because of the widespread understanding and adoption of modern filtration technologies.

So in my view, a hydraulic system running at 110°C is a hydraulic system from hell—figuratively speaking. To intentionally design such a system is like dancing with the devil. Let’s consider some of the reasons why.

Oil life

According to Arrhenius’s Law, for every 10°C increase in temperature, the rate of reaction doubles. The chemical reactions we’re concerned with regarding hydraulic oil life are oxidation, due to the presence of air; and hydrolysis, due the presence of water. The hotter the oil, the faster the rate of these reactions — and exponentially so.

To illustrate, if you pour some cooking oil into a glass, it’ll take days, even weeks before it darkens in color, which is a sign of oxidation, Figure 1. But pour the same amount of cooking oil into a frying pan — which gives the oil a large contact area with air — then heat it up, and the oil will become black in a very short time.

When asked about the issue of oil life, my colleague from the hydraulic component manufacturer admitted that when the lab tested hydraulic components at temperatures of 110°C and above for extended periods, the oil had “turned black as ink and smelt unmentionable.”

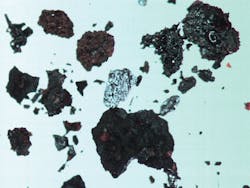

Trouble is, the oil doesn’t fail in isolation. Figure 2 shows sludge buildup on hydraulic filter media (varnish and sludge are by-products of the oil oxidation process), and Figure 3 shows oxidation debris and wear particles from a hydraulic machine that was operated at extremely high temperatures.

Oil viscosity

The operating viscosity of hydraulic oil is crucial for both adequate lubrication and efficient power transmission. The higher the maximum expected operating temperature, the wider the temperature operating window becomes. And the wider the temperature operating window, the more difficult it is to maintain oil viscosity within both allowable and optimum limits.

For example, consider a system with a cold start temperature of 5°C and a maximum operating temperature of 110°C. To maintain viscosity between 800 cSt at cold start and 25 cSt at maximum operating temperature would require an ISO VG150 oil with a viscosity index of 229! Just in case these numbers don’t mean much to you, this is not the type of hydraulic oil you can just call in and pick up from your local oil supplier. Hydraulic oils in common use have ISO viscosity grades of 32, 46, and 68. A typical monograde hydraulic oil has a VI of around 100 and a multigrade, around 150. So even if it were readily available, a VG150 oil with a VI of 229 would be a premium-priced product to say the least.

Seal and hose life

Like everything else, the elastomers used to make hydraulic seals and hoses are improving all the time. But oil temperatures above 82°C accelerate the degradation of most of these polymers. In fact, according to one seal manufacturer, operating temperatures 10°C above recommended limits can reduce seal life by 80% or more. And if temperatures are extreme enough, some polymers can actually melt, as shown in Figure 4.

Furthermore, the constant cycle of heating and cooling, a process known as aging, is more severe when temperature extremes are greater. Aging causes these polymers to lose their elastic properties. This results in leaking seals and hoses.

Conclusion

Increasing the temperature at which a hydraulic system is expected to operate does nothing to enhance machine performance. It only compounds a host of reliability issues that cannot be solved with current technologies. So it’s not progress — it’s regress. And this false progress will certainly come at cost to the hydraulic equipment owners who operate these hot-running machines.

Brendan Casey has more than 20 years experience in the maintenance, repair, and overhaul of mobile and industrial hydraulic equipment. For information, visit www.hydraulicsupermarket.com.