Symptoms typical of an aerated hydraulic system plagued the F-104 aircraft for many years. (To understand what fluid aeration is and how fluids become aerated, see chart below) Aeration was caused by system components with built-in chambers and passages wherefree air (bubbles) collected when system fluid was saturated or at rest with no pressure acting on the fluid.

The steering-damping unit of the nose landing gear on the F-104 aircraft is a typical hydraulic component. It extracts energy from hydraulic fluid by restricting flow between two chambers and thus damps nose wheel oscillation. If the fluid is aerated, the energy extracted diminishes until it reaches a level where the damping energy is below the unbalancing force of the wheel and shimmy sets in.

Several types of air extraction devices then available were tested over a span of years. Unfortunately, they were not effective in the pressure environment of the aircraft system. Finally basic studies were undertaken. Theories were explored which led to the construction and testing of a laboratory model of an air-oil separator which stopped the nose wheel shimmy.

Theory of operation

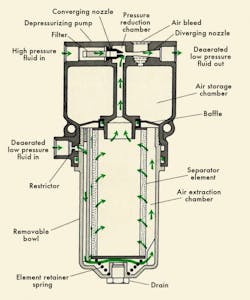

This air–oil separator operates on the principle of lowering the pressure (to a desired vacuum) in a chamber containing small quantities of hydraulic fluid continually bypassed from a pressurized dynamic system. The gases thus released from the fluid are collected and prevented from being returned to the system. The gases are stored for removal at convenient intervals when the hydraulic system is at rest.

Wire mesh screen separates bubbles

Initial attempts at actually constructing the air-oil separator involved using a 10-micron (nominal) wire mesh filter screen as a barrier because of its ability to resist the passage of air. This resistance is demonstrated by the familiar bubble test used on filter elements wherein the element does not pass an air bubble until the pressure differential is at least 9 inches of water. This premise was correct in that air did not pass through a 10-micron filter screen as long as the air was in the form of small bubbles. In other words, free air did not pass through the filter screen when the air content of the fluid was well above the saturation point.

How fluids become aerated

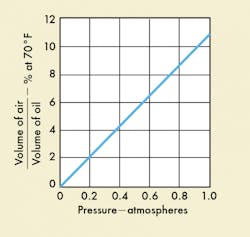

Air can enter a hydraulic system in many ways and, according to Henry’s Law, will be dissolved in a fluid in proportion to the pressure acting on the fluid. Thus, considerable quantities of air can be dissolved in a system that has a pressurized reservoir because the pressurizing media (air or a gas) is in direct contact with the fluid surface. Additional quantities of air may be introduced by aircraft servicing equipment such as hydraulic ground test stands, which also use air-pressurized reservoirs.

When the system is at rest and unpressurized, air in excess of that which can naturally be dissolved at the zero pressure condition is released as free air.

Effects of air

Air in a hydraulic system has many detrimental effects on both component and system performance. The more obvious symptoms of an aerated system are system oscillation, power loss, cavitation, increased fluid heat, response lag, foaming, and “spongy” controls. Loss of power and a “soft” system can be directly attributed to a decrease in the bulk modulus (greater compressibility) of the fluid because of an increasing air content

Aspirator vacuums air from fluid

Unfortunately, bubbles get smaller with increasing pressure. The lowest pressure in the F-104 is about 30 psig. This pressure was far too high because even at this pressure the free air bubbles would be compressed and driven through the filter screen. Total bubble removal was not possible. The next logical step was to introduce an aspirator, which would reduce the pressure in the chamber so the bubbles would expand and not penetrate the filter screen.

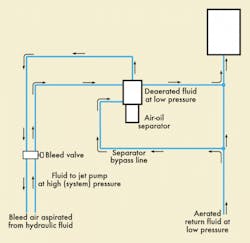

It was at this stage that the scheme to use a jet pump (aspirator) to lower the pressure in the separating chamber was tried. By lowering the pressure acting on the fluid, large quantities of dissolved and free air were released and the filter screen barrier was able to separate the bubbles from the fluid.

Air reabsorbed quickly

During the development testing it was noted that fluid release of its air by the separator would quickly reabsorb air when left in an exposed container. The deaerated fluid acted somewhat like a sponge. This phenomenon has proved very beneficial in bleeding complex systems such as that of the F-104. The most remote reaches of the system are bled effectively by circulating treated (deaerated) fluid throughout the system, reabsorbing pockets of air. Nooks and crannies that would normally never get bled using conventional bleeding methods are easily cleared of air.

On F-104 aircraft, two separators–one for each hydraulic system–are in operation whenever the aircraft hydraulic systems are used, either in flight or on ground test stand power. Extracted air is easily bled-off during ground servicing with a conveniently located pushbutton-operated bleed valve in each system that sequentially blocks jet pump flow and opens the air storage chamber to the atmosphere.

Sizing separator to system

An air-oil separator can be designed to fit most hydraulic system requirements by varying the volume of pressurized flow, separating chamber and filter size, and servicing frequency. The volume of separating flow and separating chamber vacuum pressure can be balanced by adjusting the size of the inlet restrictor. The jet pump should be sized according to the amount of pressurized flow that can be spared from the system and the amount of heat that the system can tolerate. (Pressure drop across the pump nozzle adds heat to the fluid.)

If an air-oil separator is considered during the early stages of system design, the separating filter can be integrated with system filtration requirements since the separator is ideally situated in a bypass loop of the system with relatively low flow rates and low return pressure.