The growing implementation of electrification, especially in mobile applications, has brought about the need to reassess vehicle and machine designs including their fluid power systems.

A recent survey of Power & Motion’s audience found about 50% of respondents have seen an uptick in requests from customers for electrification solutions. The other half was evenly split between those who are not experiencing an increase and those who are uncertain – indicating the varied levels of implementation in the breadth of industries served by hydraulics and pneumatics.

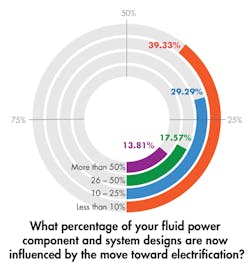

While electrification is growing, the majority of respondents said it was influencing 25% or less of their fluid power component and system designs. However, 13.81% said electrification is influencing more than 50% of their designs which demonstrates the impact it is having on some hydraulics and pneumatics companies.

Almost 70% of respondents anticipate further growth in electrification related solutions in the coming years, making it vital for the fluid power industry to continue monitoring trends in this space and evaluating its place within it.

How Hydraulics and Pneumatics Could be Affected by Electrification

As electrification has grown in many of the fluid power industry’s key markets – such as construction equipment and automotive – many companies have already developed or are working on solutions specifically for electrified applications.

In addition, much of the industry is assessing the ways in which hydraulic and pneumatic systems could be redesigned. Doing so is necessary not only to meet the unique requirements of an electrified application but also to enable performance enhancements.

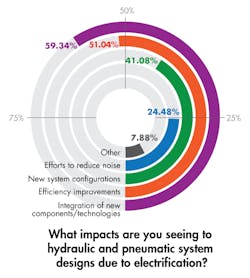

Improving the efficiency of fluid power systems is a key development area. Survey respondents noted efficiency improvements as one of the top impacts to hydraulic and pneumatic systems due to electrification – with 51.04% indicating as such. Ensuring all systems perform efficiently reduces energy draw from the battery, helping to extend time between charges which benefits vehicle range and productivity.

These efficiency gains are achieved by better applying power as it is required. “The exact power you need is given to an actuator, no more, no less,” said Carl Seguin, in charge of engineering at Smart Reservoir Inc., in an interview with Power & Motion.

Traditionally, a hydraulic pump runs at a constant speed even though it does not need to, explained Seguin. This causes excess energy to be created and wasted, equating to inefficiencies. Use of variable frequency drives (VFD) has grown in recent years to allow changes in pump speeds for more accurate, efficient flow. “That's a positive side of electrification, [using] the right amount of energy to do work,” he said.

The largest impact noted by survey respondents, at 59.34%, is the integration of new components and technologies. This can include integration of more electronics, such as sensors, to improve precision which can aid with efficiency improvements.

Additional impacts respondents pointed to include the creation of hybrid hydraulic systems and energy recovery capabilities. The latter is not new, but a growing method within hydraulic systems to aid efficiency improvements. Sun Hydraulics’ ENERGEN valve is a recently introduced example. The valve converts hydraulic flow into electric energy by capturing and converting otherwise wasted energy. It essentially acts as regenerative braking for fluid power said one company executive during an interview with Power & Motion at the International Fluid Power Exposition (IFPE) 2023.

Drive System Design – an engineering consultancy focused on future powertrains and associated technologies – sees customers who have traditionally used hydraulics for propulsion or auxiliary components considering replacing some or all of them with electrified counterparts said Jason Schneider, Principal Engineer - Team Lead, Electrified Powertrain, in an interview with Power & Motion. “There's efficiency improvements to be had and controllability improvements,” he said. “And there's even things on the NVH (noise, vibration and harshness) side [because] electronics are typically quieter than hydraulics and pneumatics, and maintainability as well.”

Initial components typically considered are mechanically driven pumps or hydraulic motors which could be replaced with electric motors. If replacing those, hoses and other components feeding into the pump or motor can also be replaced which can provide space and weight savings – helping to ensure efficient battery use.

READ MORE: Drive System Design Introduces New Method for Electric Motor Development

Electrification Brings Opportunities for Fluid Power

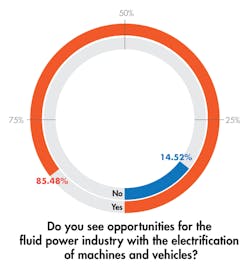

An overwhelming majority of survey respondents, just over 85%, see opportunities for the fluid power industry due to electrification. Much of this comes from the technological changes noted previously. Many respondents indicated the ability to improve precision and control, benefitting efficiency as well as the productivity of a machine – more precise movement of an excavator arm, for example, helps to reduce rework which keeps projects moving in a timely manner.

One respondent noted the better control provided by some systems could help to justify the additional costs and complexity associated with electrification.

It is possible to rethink the size, layout and other design aspects of fluid power systems as well. One survey respondent noted the ability to reduce the physical size of hydraulic power units (HPU) as an opportunity. Doing so can help to minimize space claim which is an important consideration, especially in mobile applications as batteries account for much of the space and weight in a vehicle. Reducing the size of other components helps to compensate for this.

Additionally, power needs may be reduced compared to traditional applications therefore a smaller HPU is more desirable from a cost and energy consumption standpoint.

For its proof-of-concept wheel loader electrification project, Danfoss Power Solutions’ Editron division found rethinking the entire system architecture of the machine was the best approach. This included a reassessment of the hydraulics system. By separating the propel and hydraulic work functions, the company found it could improve the efficiency of these systems and the overall machine.

Watch our video interview with Kimmo Rauma, vice president of Danfoss' Editron division, to learn more about the wheel loader conversion project.

Additional opportunities cited by respondents which electrification could bring to fluid power include the ability to improve accuracy and repeatability, reductions in oil leaks – and thus environmental impacts – increased use of electrohydraulics, and easier implementation of closed loop controls, to name a few.

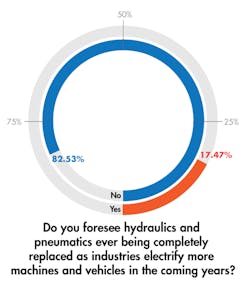

However, it was also evident from the survey, and most discussions the Power & Motion team has with members of the industry, that hydraulics and pneumatics are not going anywhere. Over 82% of survey respondents said they do not foresee fluid power components ever being completely replaced as electrification continues to grow.

While there have been some examples of hydraulic systems being replaced with electric actuators and other electronic components – most notably Moog Construction’s work with equipment manufacturers Komatsu and Bobcat – many note the power density provided by hydraulics will still be required in many applications, such as large construction equipment.

READ MORE

Moog and Komatsu Develop All-Electric Wheel Loader

“Electrified systems won't be able to supply the same amount of power for the higher power applications where pneumatics or hydraulics are currently used,” said Schneider. In some applications it will not be possible to achieve electrification or even make sense to do so, necessitating a thorough evaluation of the application and its requirements.

Technology and Industry Challenges Remain

One of the top challenges associated with implementing changes or new solutions for electrification for survey respondents, at 50.42%, is uncertainty about what technologies would be beneficial. This was closely followed by 40.34% indicating the lack of industry information as a challenge.

Both were factors the National Fluid Power Association (NFPA) set out to address when it established its electrification task force in 2022. The task force brought together members of the industry to discuss implications of electrification for the fluid power industry as well as help provide hydraulics and pneumatics manufacturers with more information on this trend.

NFPA’s Electrification in Fluid Power Task Force released a report in early 2023 containing its final consensus which will be used to educate the industry and help the association refresh its Technology Roadmap – a project which is currently in process and guides the technology needs of the fluid power industry.

The report defines electrification and its many terms, predicted impacts to fluid power as well as ways the industry could effectively market the hydraulics and pneumatics technologies which will still be required for years to come.

Another key challenge noted by survey respondents was the complexity of systems due to electrification. Schneider said some of this comes from the increased controllability brought about by inclusion of electronic components. “If you want to do more clever things to get more efficient, you're going to drive the complexity of the controls,” he said which can be a challenge for design teams.

The inclusion of more sophisticated electronic components will also bring a need to appropriately train technicians when repairs are necessary, said Seguin. Though electronics may require less maintenance than hydraulics and pneumatics, specialized training is necessary to not only understand potential issues when they arise but also ensure safety while working with these systems.

READ MORE: How to Safely Work with High-Voltage Systems

Survey respondents also noted challenges associated with customer hesitation, the lack of available technology and the need for a skilled workforce capable of developing necessary technologies.

According to Sequin, there are many pros and cons to consider with electrification such as the efficiency gains possible through improved control of hydraulic components. However, there is also the need to consider the larger factors associated with electrifying vehicles and machines such as the charging infrastructure necessary, where the energy to power so many electric vehicles will come from as well as the higher initial costs of going electric.

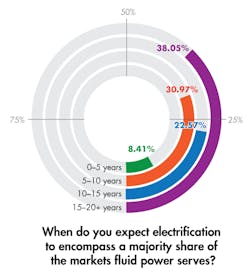

While there has been rapid growth of electrification in recent years, it remains unclear just how much it will become a part of the industries served by fluid power. A number of survey respondents believe it will take another 15-20 years before electrification encompasses a majority share of the markets utilizing hydraulics and pneumatics. However, this was closely followed by those who see it becoming more prevalent in the next 5-10 years.

There are several factors driving the push toward electrification and despite the confusion and complexity it is causing for many in the fluid power industry, it is also presenting several opportunities which could benefit hydraulics and pneumatics in the long term.