The National Fluid Power Association (NFPA) is in the midst of its biannual update to its Technology Roadmap for the Fluid Power Industry. Through this roadmap the association provides a look at industry needs, how fluid power can potentially meet those needs as well as research and development objectives to help meet current and future industry requirements.

In order to best determine the needs and objectives outlined in the roadmap, NFPA surveys the industry for its input. In addition, the NFPA Roadmap Committee helps to oversee the process and is lead by members working in hydraulics and pneumatics. Bradlee Dittmer of NORGREN is the chair for the 2023 Roadmap Committee and Steve Meislahn of Sun Hydraulics/Helios Technologies is serving as vice chair.

READ MORE about the Technology Roadmap and what industry needs were outlined in the 2021 edition.

Industry Sets Technology Development Targets

NFPA initiated the process for the 2023 update to its Technology Roadmap in December 2022. The first step was to survey the industry on technology drivers for fluid power customer markets and determine key customer drivers which will help to create a framework for the roadmap.

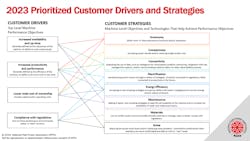

The association defines a customer driver as a top level performance objective that machine builders in the markets served by fluid power have for their machines while a customer strategy is a machine-level objective or technology that is currently being deployed to help those machine builders achieve their performance objectives.

After reviewing the survey results, the NFPA Roadmap Committee determined there are four key customer drivers for the fluid power industry in the coming years:

- Increased availability and up-time. Generally defined as the robustness of the machine, its ability to work continuously.

- Increased productivity and performance. Generally defined as the efficiency of the machine, its ability to do more work in less time.

- Lower total cost of ownership. Includes capital and/or operating costs.

- Compliance with regulations. Such as those pertaining to environmental, safety, or other concerns.

Eight customer strategies were outlined as well:

- Autonomy. Either semi- or fully-autonomous functions and/or operations.

- Compactness. Increasing power density and/or reducing weight and/or size.

- Connectivity. Expanding the use of data, such as intelligence for cloud-based condition monitoring, integration with site management systems, and/or communicating machine status for other value-added purposes.

- Electrification. Decarbonizing prime movers through a variety of strategies.

- Energy Efficiency. Increasing it; and including strategies to improve battery life and/or charging and to use less energy and/or reduce emissions.

- Maintenance. Making it easier; and including strategies to ease the serviceability of the machine and to increase the availability of repair and replacement parts.

- Materials. Use of conflict and/or environmentally friendly materials in strategic ways to better comply with regulations.

- Noise. Reducing perceived noise levels and/or improving noise pulsation.

Understanding these drivers and strategies will help the fluid power industry ensure it is developing technologies which meet customer requirements.

In addition to the fluid power industry providing its input, several partner associations which represent key customer markets are also aiding the roadmap process. These include the Association for High Technology Distribution (AHTD), the Power Transmission Distributors Association (PTDA), the Packaging Machinery Manufacturers Institute (PMMI), the Association of Equipment Manufacturers (AEM), and the Association for Manufacturing Technology (AMT).

READ MORE: 3 Key Technology Trends at IFPE 2023

Next Steps will Expand Roadmap Objectives

Now that the customer drivers and strategies have been determined, the NFPA Roadmap Committee's next step is to establish the fluid power industry's capability improvements. This means evaluating how hydraulic and pneumatic systems may need to be improved in order to meet or better meet the outlined customer drivers and strategies.

To help determine this, NFPA has launched two new surveys to get input from across the fluid power industry. One survey is focused specifically on hydraulic improvements and the other on those for pneumatics:

- Hydraulic survey = https://www.surveymonkey.com/r/5XBY2FV

- Pneumatic survey = https://www.surveymonkey.com/r/53H38H2

Either or both surveys can be completed based on areas of expertise; the NFPA is looking to have insights provided by February 16, 2023.

The Roadmap Committee will then meet again on March 2 to review the survey results and determine the what technology improvements the industry could make to further flush out the roadmap and its objectives. NFPA welcomes more members of the fluid power industry to join the committee or be part of the roadmapping process; those who are interested can contact Eric Lanke at [email protected].

For more on the process and steps completed to date, a dedicated project website has been created at which a copy of the Roadmap Committee's full report can be downloaded.