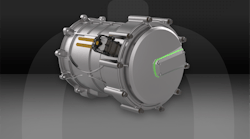

Terzo Power Systems has introduced a new version of its electrohydraulic system to enable electrification of larger vehicles and equipment. The Hydrapulse Frame Size 3 (Hydrapulse F3) provides increased power density to meet the needs of commercial trucks as well mining and other large off-highway equipment.

The new Hydrapulse F3 is the company's largest model to date. It features power levels up to 100 kW and 800V of direct current. Multiple units can be used in tandem, as well, to provide even more power for larger vehicle and equipment applications.

"The F3, like every Hydrapulse, has some unique features worth highlighting," says Mike Terzo, CEO, Terzo Power Systems, in the company's press release announcing the launch of the Hydrapulse F3. "The inverter and liquid cooling are integrated, which makes plug and play much simpler for OEMs. These factors, combined with the power-on-demand capabilities of the F3, solve many of the problems encountered in off-highway electrification."

Versatile drive and mounting options will be available with the Hydrapulse F3, as well as other features including:

- Direct Drive

- Planetary Drive

- SAE “B” or “C” Mount

- Fixed Displacement Pump

- Hydrostatic Drive

Watch Terzo Power Systems' video highlighting additional features of the Hydrapulse F3.

Hydrapulse Blends Electric and Hydraulic

Hydrapulse was developed to help improve the efficiency of hydraulic systems and enable the electrification of off-highway equipment. It is comprised of an electronically controlled motor and pump assembly which enables it to efficiently perform several types of fluid power functions. Integration of the Hydrapulse's various components helps to ensure optimized performance while also creating a compact system.

The Hydrapulse is a plug-and-play system for easy installation for OEMs. It is customizable but also comes in three standard sizes. Additional features include:

- rugged IP6K9K rating

- wide voltage input range

- liquid cooling

- custom mounting options

- quiet pump options

- production ready design.

Since introducing the Hydrapulse technology, Terzo Power Systems has demonstrated its capabilities in construction equipment and expanded the applications in which it can be utilized such as heavy-duty trucks.

The company has also expanded partnerships with other component suppliers to provide OEM customers with a full system solution. In June 2021, it announced a partnership with Briggs & Stratton whose Vanguard commercial lithium-ion battery pack will provide electricity to the Hydrapulse unit.

Terzo Power Systems most recently (February 2022) entered into a partnership with Continental/Hydreco to build steering and electrohydraulic systems for OEMs. Continental/Hydreco components are used in various off-highway equipment applications. As such, they are able to meet the demands of these machines while ensuring durability all of which will benefit use of the Hydrapulse in heavy equipment.

Continental/Hydreco also offers silent pump products which will be particularly beneficial in electric vehicle applications. The pumps reduce the amount of fluid borne noise generated and transmitted, helping to minimize noise from the overall hydraulic system. Electric vehicles are known for their quieter operation because of the lack of an engine and other supporting parts which means other components and systems will need to begin operating at quieter levels as electrification increases to ensure comfort of operators.