Pressure- or fatigue-testing machines often require high pressure for long periods of time. Other circuits might need a small volume of high-pressure fluid for a short period while most of the cycle only needs low pressure. Other machines can use air cylinders to manipulate a part but need very high pressure to perform one operation. Some manufacturers make high-pressure rotary pumps — rated up to approximately 10,000 psi — but these pumps are expensive and may heat the fluid. Another choice for low-volume/high-pressure circuits is an intensifier.

When a circuit calls for a small volume of high-pressure oil or air, consider using an intensifier — sometimes called a booster. Most cylinder manufacturers build air- or hydraulic-powered intensifiers. Or you can use off-the-shelf cylinder parts to assemble your own booster. Also, intensification is a natural function of single-rod cylinders and motor-type flow dividers.

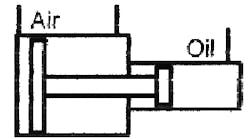

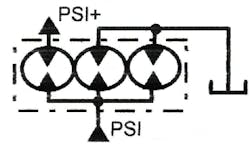

Figure 13-1 pictures the symbol for an air-oil intensifier. While the symbol shows two pistons with different diameters, the actual intensifier consists of a piston pushing a rod. The large-area air piston pushes a small-area hydraulic ram against trapped oil. The difference between the two areas gives high-pressure capability at the small ram. This capability is indicated by the area ratio. If the air piston has a 5-in. diameter and the oil piston has a 1-in. diameter, the area ratio is 25:1. With this area ratio, 80 psi acting on the air piston produces 2000 psi at the hydraulic piston.

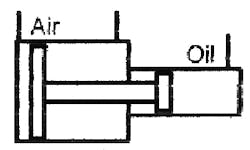

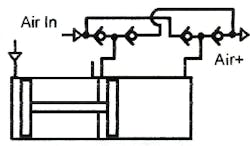

Stroke length dictates the maximum volume of high-pressure fluid from an intensifier configured as in Figure 13-1. The booster in Figure 13-2 produces the same pressure but an unlimited volume. A reciprocating intensifier takes fluid from a reservoir and forces it into the circuit. In effect, the reciprocating intensifier is a single-piston pressure-compensated pump. The area ratio and air pressure determine the maximum hydraulic pressure. This pump is close to 100% efficient, so oil heating is not a problem. Intensifiers do not need relief valves because they stall at maximum pressure.

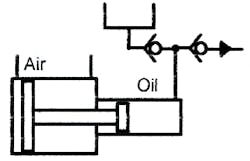

The oversize-rod cylinder shown in Figure 13-3 also is an intensifier. Any single-rod cylinder intensifies pressure with the rod end port blocked. The larger the rod diameter, the greater the intensification. For low intensification — say 1.5 to 2 times system pressure — a single-rod cylinder is inexpensive and readily available.

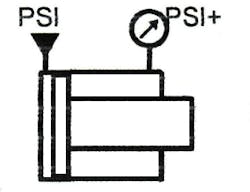

Figure 13-4 depicts the symbol for a motor-type flow divider used as an intensifier. This type intensifier produces a continuous flow of higher-pressure oil at a reduced flow rate. The reduced flow rate is the same ratio as the pressure increase. (A 2:1 intensifier reduces the flow by 50%.) A motor-type flow divider intensifier is less efficient than a piston-type intensifier and is not recommended for applications with long holding periods.

Figure 13-5 shows the symbol for an air-to-air intensifier. These intensifiers produce small volumes of higher-pressure air from the plant air supply. Ratios up to 4:1 are common. Hydraulically driven designs with higher ratios are available from some manufacturers.

Intensifier circuit using standard cylinders

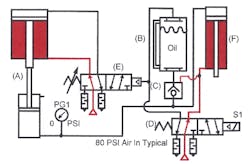

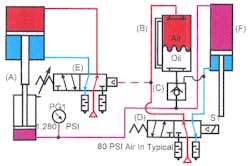

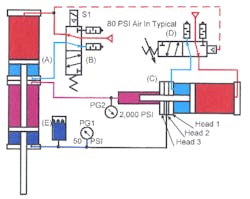

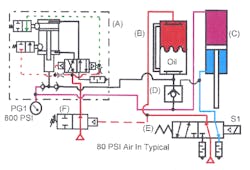

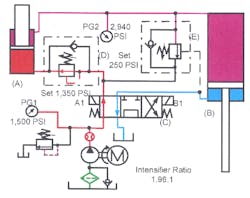

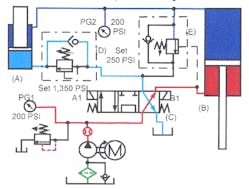

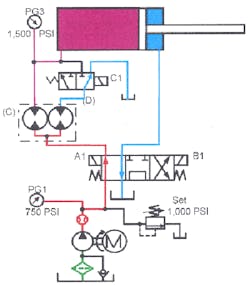

The schematic diagram in Figures 13-6 through 13-9 suggests how to use standard cylinders as an air-hydraulic intensifier. This is a quick way to get high ratio intensification for a rush job. A 6-in. bore air cylinder driving a 1.5-in. bore hydraulic cylinder gives an intensification ratio of 16:1. With 80-psi input air, hydraulic output pressure is approximately 1300 psi.

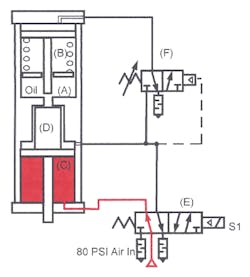

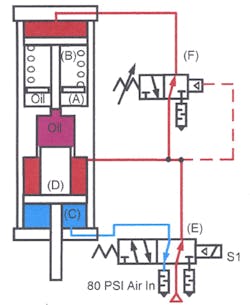

Mount the cylinders to a beam or machine member and pipe them as shown in the Figures 13-6. This circuit allows a hydraulic cylinder to operate at low pressure during extension and retraction, with a short high-pressure work stroke to clamp, punch, or do other work. The circuit includes shop-made intensifier A, air-oil tank B, air-pilot-operated hydraulic check valve C, solenoid-operated 5-way air valve D, sequence operated 5-way air valve E, and work cylinder F. With solenoid S1 deenergized, the cylinder and intensifier stay fully retracted, ready for a work stroke.

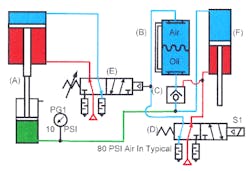

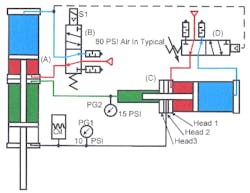

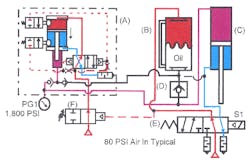

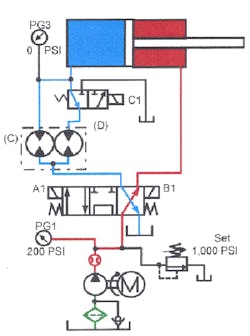

Energizing solenoid S1 on valve D, as in Figure 13-7, directs air to air-oil tank B and exhausts the rod end of cylinder F. Oil from the air-oil tank free-flows through check valve C to extend the cylinder rapidly. Pressure in the line to the cylinder’s cap end remains low as the cylinder moves toward the work, so sequence valve E stays in its normal position. The cylinder extends until it contacts the work.

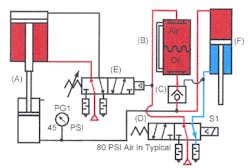

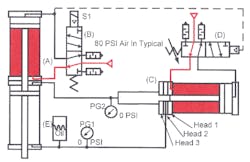

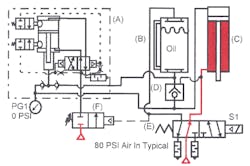

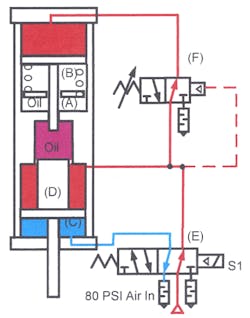

After the cylinder contacts the work, pressure in its cap-end port increases. Figure 13-8 shows the circuit condition after this pressure buildup shifts sequence valve E. When sequence valve Eshifts, air goes to the cap end of the 6-in. cylinder on intensifier Aand exhausts from its rod end. Cylinder Aextends to stroke the 1-1/2-in. hydraulic cylinder. This forces high-pressure oil to the cap end of work cylinder F. Check valve C is held closed by its spring to block high-pressure oil from going to air-oil tank B. Pressure in the cap end of cylinder F rises to approximately 1300 psi — and is available to power any high-force operation.

The intensifier’s hydraulic cylinder must provide enough oil to move the work cylinder through its high-pressure stroke. A 3.25-in. bore work cylinder with a high-pressure work stroke of 0.75 in. requires a minimum 6.22 in.3 intensifier volume. Calculate volume by multiplying the area of the working cylinder by the length of the high-pressure work stroke. To figure the minimum intensifier stroke, divide the volume required for the work cylinder by the area of the intensifier. In this example, the minimum intensifier stroke is 3.5 in. To make sure there is always enough high-pressure oil to do the job, add 1.0 to 1.5 in. to the intensifier stroke to allow for oil compressibility, hose stretch, and possible future needs. Choose an intensifier stroke of at least 5 in. for this application.

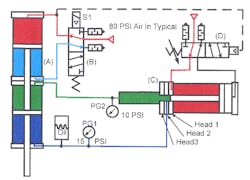

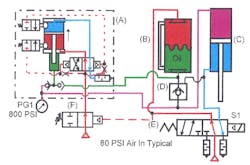

Deenergizing solenoid S1 on valve D, Figure 13-9, directs air to the rod end of cylinder F and to the pilot port of air-pilot-operated check valve C. Check valve C opens, providing oil from the cap end of cylinder F with a free path to tank. Pilot pressure to sequence valve E drops when valve D shifts. When sequence valve E returns to its normal position, intensifier A retracts and fills the intensifier cylinder with oil for the next cycle.

Notice that as cylinder F retracts, only 80-psi air pressure drives it. There is ample hydraulic pressure to extend the cylinder for the high-force work stroke, but only air pressure to retract it. If a higher retracting force is needed (to disengage tooling or for other reasons), external help or other circuit changes may be necessary.

Adjust hydraulic pressure to the cylinder with a regulator in the air line connected to sequence valve E. With a regulator to adjust the air pressure, changing hydraulic force is simple.

Hydraulic cylinder F should have resilient seals that keep oil from leaking to the air side or air to the oil side. Some circuits use two air-oil tanks on cylinder F to prevent aeration of the oil. (Chapter 3 has information about sizing and hooking up air-oil tanks.)

Three-head intensifier circuit with tandem cylinder

Several manufacturers produce 3-head intensifiers that eliminate external pilot-operated check valves. The first head on a 3-head intensifier has an air seal on its rod facing the air side and a hydraulic seal facing the oil side. The second head has an oil port into the rod chamber and a resilient seal facing the third head. The third head has a welded-on oil chamber that the piston rod enters. When the piston rod advances, it displaces oil from this chamber to create high pressure. The ratio of the air-piston area to the rod area intensifies the pressure by up to 40:1, or even higher. A standard 5-in. bore air cylinder with a 1-in. diameter piston rod produces 25:1 intensification. (This is a standard size for several manufacturers.) Three-head intensifiers supply a small volume of oil for short high-pressure work strokes. Calculate the high-pressure oil volume by multiplying the rod area by the stroke length after the rod passes the seal between the second and third head.

Figure 13-10 shows how 3-head intensifier C pressurizes air-oil tandem cylinder A. This circuit provides rapid low-force advance and retract strokes, with a short high-force work stroke when the cylinder meets resistance. Solenoid-operated directional valve B extends the air part of the tandem cylinder. Sequence valve D operates intensifier C. Sealed expansion tank Ereceives oil from the tandem cylinder while it extends at high pressure. For an expansion tank, mount an air filter with a clear bowl upside down, and remove the filter element. The transparent bowl makes it easy to check oil levels. This circuit eliminates air-oil tanks to make the system more compact. Figure 13-10 shows the circuit at rest.

Shifting solenoid S1 on valve B, as in Figure 13-11, makes the air-oil tandem cylinder advance rapidly to the work. Oil in the double rod-end cylinder transfers from front to back through the center head of intensifier C. (Keep these transfer lines short with oil velocity below 4 fps to minimize pressure drop.) As the cylinder advances, pressure at the cap port stays low. Adjust the spring on sequence valve D to cycle the intensifier after the tandem cylinder contacts the work.

At this contact, sequence valve D shifts to start intensifier C stroking forward, as in Figure 13-12. When the intensifier rod passes through the seal between heads 2 and 3, pressure intensification begins on the back of the double rod-end cylinder. As the tandem cylinder extends, trapped oil from the front chamber goes into expansion tank E. (Pressure increases slightly in the tank because the air trapped above the oil is compressed.) Use a tank with three to four times the volume displaced by the cylinder during the high-pressure work stroke. As the intensifier continues to stroke, increased pressure performs the work.

It is important that the intensifier contains enough oil to move the tandem cylinder through its high-pressure stroke. If the double-rod cylinder has a 3.25-in. bore with a 1.375-in. rod, and the high-pressure stroke is 0.375 in., then a minimum of 2.55 in.3 of oil is needed. Add considerations for oil compressibility plus line and cylinder tube expansion to the cylinder high-pressure stroke volume. Remember: line expansion is greater when using flexible hose. Determine the volume of oil in the high-pressure portion of the piping and cylinder, and then increase this volume by 0.5% per thousand psi of pressure. Often it requires 0.5 to 1.5 in.3 of oil at 2000 psi to make up for oil compressibility. Calculate oil compressibility and add it to the stroke volume so the intensifier does not bottom out before the oil reaches the desired high pressure. On most 3-head intensifiers, add 2.0 in. to the stroke required for volume to make up for oil that bypasses the rod before it enters the high-pressure seal between head 2 and head 3.

Figure 13-13 shows the intensifier and cylinder retracting. Deenergizing solenoid S1 on valve B lets sequence valve D spring-return to its normal condition. The intensifier starts retracting at high speed, but the tandem cylinder moves slowly. When the intensifier passes the high-pressure seal between heads 2 and 3, the tandem cylinder quickly returns to its home position.

Reciprocating intensifier for increased volume

A single-stroke intensifier produces a limited volume of high-pressure fluid. Pressure stops building when a single-stroke intensifier reaches the end of its stroke. If cylinder seals or piping leak, a single-stroke intensifier may build pressure, but then quickly lose it. When a circuit needs unlimited high-pressure volume at low flow, use a reciprocating intensifier.

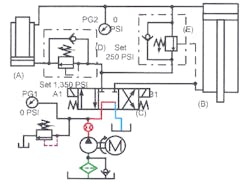

Figures 13-14 through 17 show a reciprocating intensifier powering a cylinder that must hold clamping pressure for days. Reciprocating intensifier A, air-oil tank B, pilot-operated check D, solenoid valve E, and sequence valve F advance cylinder C to the work rapidly. This arrangement can hold as much as 3200 psi for long periods without wasting energy or generating heat.

Several companies assemble reciprocating intensifiers with a directional valve, limit valves, and check valves in a unit. Special-order units may come with air-oil tanks, special valves, or accumulators — all pre-piped for operation. When supplied with pressurized air, the unit in Figure 13-14 cycles and pumps oil until it reaches a maximum pressure. Other units operate from a pilot signal whenever the machine requires intensified pressure. For even higher pressures, dual or triple air pistons give higher ratios. Double-acting intensifiers increase oil volume while using less air. Most manufacturers offer single-acting intensifiers as standard and double-acting intensifiers as an option. When a machine needs a low to medium volume of high-pressure oil and has long holding times, use a reciprocating intensifier.

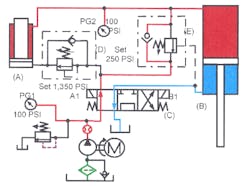

The circuit changes as shown in Figure 13-15 after the cylinder contacts the work. The intensifier starts cycling because pressure buildup shifts sequence valve F to open. Pilot-operated check valve D closes, blocking pressure fluid from going to tank. Pressure in cylinder C is already at 800 psi. As the intensifier retracts, suction draws oil in through the right-hand check valve to fill the oil chamber. Its spring and the pressure already in the work cylinder hold the left-hand check valve closed. A reciprocating intensifier is a low-volume, single-piston, pressure-compensated pump that continues to move fluid until it reaches maximum pressure. Because output from the intensifier is intermittent, cylinder movement is jerky, as is the rate of pressure increase.

Figure 13-16 shows the intensifier changing from filling mode to pumping mode. The reciprocating air piston depresses the upper cam valve, reducing pressure on the right end of the double-bleed valve and causing it to shift. Both check valves close at this time, trapping oil in the cylinder. The intensifier now starts its pumping stroke.

The intensifier is extending and discharging fluid through the left check valve to the actuator in Figure 13-17. Fluid fills the actuator and pressure increases. The intensifier continues to reciprocate until it reaches maximum pressure. At maximum pressure, the intensifier stalls but continues to make up for internal or external leakage.

With the addition of an accumulator, a reciprocating intensifier could supply cylinders or motors that operate intermittently. The accumulator stores oil during machine idle time, and then discharges it at high flow without pulses for short periods. Use flow controls to slow the rapid uncontrolled movements likely to occur when using an accumulator.

Oversize-rod cylinder as an intensifier

There are times when the operating pressure of a hydraulic system is too low to produce enough force on a cylinder. The pump’s rated pressure may be inadequate or the electric motor has too little horsepower for the higher pressure. Also, other actuators in the system may not be able stand higher pressure. One answer to this problem is a hydraulic cylinder piped as an intensifier.

When a single-rod cylinder extends, pressure in the rod end intensifies if there is any resistance to flow out of it. Resistance could be from a flow control, counterbalance valve, or simply a restriction. The amount of intensification depends on the area differential of the cap end to the rod end of the cylinder. A typical 4.0-in. bore cylinder with a 2.5-in. oversize rod is sold as a 2:1 ratio. All standard interchangeable cylinders use standard bore and rod sizes that are close to but not greater than a 2:1 ratio. The 4.0-in. bore, 2.5-in. rod combination actually has 1.64:1 area differential. With the rod-end port blocked, a 1.64:1-ratio cylinder produces 1640 psi at the rod end if the cap-end pressure is 1000 psi. This intensified fluid might cause problems in a typical circuit, but could supply a small volume of higher-pressure oil for a short, high-force work stroke from a cylinder.

The volume of oil entering and leaving the intensifier cylinder has the same ratio as the intensification. In the 1.64:1 example above, with a cylinder cap-end flow of 10 gpm, pressure intensified flow from the rod end is 6.1 gpm. The larger the cylinder rod, the higher the intensified pressure — and the lower the flow.

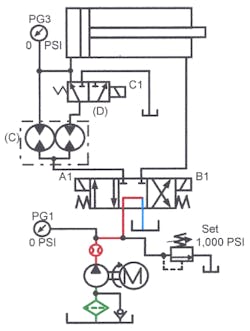

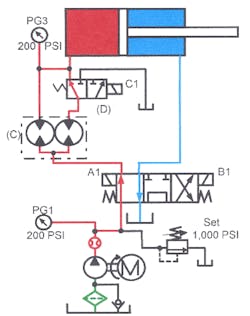

Figure 13-18 shows a schematic diagram of an oversize-rod cylinder used as an intensifier. Intensifier cylinder A has 5.0-in. bore with a 3.5-in. diameter rod. The area of the cap side is 19.64 in.2 and the rod annulus area is 10.01 in.2, giving a ratio of 1.96:1. Every 100 psi in the cap end produces 196 psi in the rod end. Also, 10 gpm entering the cap end pushes 5.1 gpm from the rod end. Stroke length of intensifier cylinder A must give enough volume to move work cylinder B through its high-pressure work stroke. If cylinder B has a 10.0-in. bore and a 0.5-in. stroke, the required volume is approximately 40 in. 3. Dividing the 40-in.3 work-stroke volume by a 10-in.3 intensifier volume indicates that a minimum stroke of 4 in. is needed from cylinder A. To allow for oil compressibility and leakage, specify an intensifier stroke of 6 to 8 in.

The cycle is automatic because sequence valves D and E control extension and retraction of the intensifier. Cycle time is slightly slower than the original low-force circuit.

Figure 13-19 shows solenoid A1 on directional valve C energized. Fluid flows directly to work cylinder B through the free-flow check on sequence valve E. Work cylinder B advances rapidly toward the work at low pressure.

At work contact, pressure builds to the setting of sequence valve D, Figure 13-20. Intensifier cylinder A extends and pressurizes oil in the cap end of work cylinder B to approximately twice system pressure. Before the intensifier bottoms out, it must give enough volume to complete cylinder B’s work stroke. For long holding cycles, calculate valve and cylinder leakage, then add extra intensifier stroke so pressure holds.

To retract work cylinder B, energize solenoid B1 to direct oil to its rod end, as in Figure 13-21. As cylinder B retracts, sequence valve E forces oil from its cap end to retract intensifier cylinder A. This saves pump fluid and retracts the intensifier within normal cycle time. When intensifier cylinder B retracts fully, external pilot-operated sequence valve E opens and the remainder of the oil in the work cylinder cap end goes to tank. The only added cycle time is while the intensifier boosts pressure in the work cylinder.

Motor-type flow divider as an intensifier

A motor-type flow divider intensifies pressure at one outlet when the other outlet is at a lower or no pressure. In the case of a 2-outlet motor flow divider with equal displacements, when inlet pressure is 1000 psi, one outlet can be at 2000 psi while the other outlet is 0 psi. While pressure doubles, flow from the intensified outlet is one half that at the inlet. The energy from the zero outlet motor transfers to the other motor to produce intensified pressure.

With more than one section going to tank, say from a 4-outlet divider with three outlets to tank, intensification would be four times. While the intensified fluid is four times inlet pressure, volume is only one-fourth inlet flow.

Using motor dividers with unequal sections is another way to get high intensification. If the motor in one section discharges 3 gpm to tank and the other section sends 1 gpm, intensification is still 4:1.

Figures 13-22 through 25 show how to use this feature of motor-type flow dividers in a circuit. This circuit has equal flow divider C and 3-way directional valve D in the cylinder cap end line. In the at-rest condition, both outlets of the flow divider connect to the cap-end port.

In Figure 13-23, the cylinder is extending at full speed and low thrust. Shifting solenoid A1 of the directional valve ports oil through one side of the divider and 3-way valve to the rod-end port. Fluid from the other side of the divider goes directly to the cylinder rod-end port. Size the pump and valves to provide enough flow for the speed required in the fast-forward portion of the cycle. Normally, motor horsepower is low for a cylinder moving a light load.

When the cylinder makes a limit switch, as in Figure 13-24, it energizes solenoid C1 on the 3-way valve. When the valve shifts, oil from one section of the motor flow divider goes to tank. Pressure doubles, while cylinder speed drops to half what it was before energizing solenoid C1.

This circuit works best on actuators that do not stall. Using this setup for a fast advance and clamping operation might result in excess heat from internal leakage in the flow divider during the clamping part of the cycle.

Energizing solenoid B1, Figure 13-25, makes the cylinder retract. Oil from the cap-end port flows through both sections of the flow divider, then back to tank through the directional valve.

When using a motor-type flow divider as an intensifier, make sure it is capable of operating at the elevated pressure. Pressure rating of an inexpensive gear motor flow dividers may be only 2000 psi intermittent and 1500 psi continuous. Some gerotor flow dividers go as high as 4500 psi intermittent and 3000 psi continuous.

Special air-oil intensifier cylinder

Some manufacturers build self-contained, air-driven, high-force hydraulic cylinders. These units look like a very long stroke air cylinder. Typically, they have 2 to 10 in. total strokes with 1.0- to 1.5-in. high-force strokes. They often replace a hydraulic unit on a machine that needs high tonnage for one operation on an otherwise air-powered circuit. Because these special intensifiers are self-contained, they only require an air supply and a signal to start them. They have sealed reservoirs so they operate in any position. They normally have an indicator to monitor oil volume for preventive maintenance. According to bore size and stroke length, cycle rates go as high as 150 per minute. The bigger the bore and longer the stroke, the fewer the cycles per minute.

As with other air-oil devices, return power is only cylinder net rod-end area multiplied by air pressure. The unit may have 50 tons to punch a hole but only 0.5 ton to retract the punch. For high retraction force use springs or urethane strippers, or add short-stroke return cylinders.

Figure 13-26 has a cutaway view of the intensifier cylinder at rest. (This view only shows function, not necessarily an actual assembly.) Air piston and rod C with attached hydraulic ram D move rapidly at low force to the work and return the tooling at the end of the cycle. Ram D is the area that intensified oil pushes on to get the short, high-force work stroke. Spring-loaded, floating piston A forms the top of a variable-volume, sealed oil tank. Spring-return air piston B drives its piston rod into trapped oil to intensify pressure for the work stroke. Directional control valve E cycles the advance and return strokes of cylinder C, and supplies air to pilot sequence valve F, starting the high-pressure work stroke.

When directional valve Eshifts, as in Figure 13-27, air piston-and-rod C extends the tooling to the work rapidly. As the piston-and-rod extend, ram D advances and fills with oil from the variable-volume tank. Vacuum forms in the chamber behind ram D, and the spring behind the floating piston forces oil into the void. Piston-and-rod C continues to advance and oil transfers until the work is met. This low-force advance stroke moves quickly (and uses air flow controls when necessary). Seals on ram D separate oil and air.

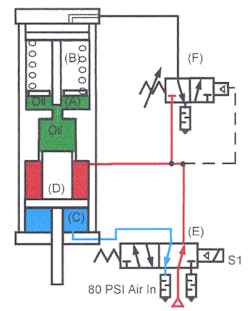

Figure 13-28 shows the intensifier after contacting the work. When air piston-and-rodC stop against the work, pressure build-up behind the piston shifts sequence valve F. When sequence valve F shifts, shop air extends spring-return air piston B. The first movement of the spring-loaded air piston advances the rod to the flow port connecting the tank to the chamber behind hydraulic ram D. As the rod enters this flow port, it passes through a resilient seal, stopping flow to tank and sealing the chamber behind ram D. This action automatically isolates the low-pressure chamber — eliminating the need for a pilot-operated check valve.

As the spring-return air piston continues to extend, as in Figure 13-29, the rod displaces oil in the chamber behind hydraulic ram D. In this case, the area of spring-return piston B is 15 times the area of the rod entering the sealed chamber. The air piston and rod continue to displace oil and move hydraulic ram D until the pressure behind the ram becomes 15 times greater than the air pressure on the piston. The stroke of spring-return piston B and the diameter of its rod set the maximum high-pressure work stroke. The higher the intensification ratio and the shorter the stroke, the less the high-pressure stroke capability.

Deenergizing directional valve E allows the spring loaded air piston and the work cylinder to return home. The work cylinder returns slowly while spring return air piston B retracts past the high-pressure seal.

Air-to-air intensifiers

Instead of buying a high-pressure compressor when only a small volume of compressed air is needed, consider using an air-to-air intensifier. Air-to-air intensifiers are small self-contained units that operate automatically as long as they have a supply of compressed air. Figure 13-30 shows a generic schematic of a simple air-to-air intensifier made from stock cylinders and valving. The arrangement has two cylinders connected at their rod ends and mounted on a beam, with limit switches or limit valves, a directional control valve, and four check valves. As long as compressed air is supplied to the intensifier, it takes in atmospheric air, compresses it, and sends it to a receiver and/or the system.

As the cylinders in Figure 13-30 stroke to the left, the intensifier takes in atmospheric air at the cap end of the 3.0-in. bore cylinder. Compressed air discharges from the rod end to a high-pressure receiver. After the cylinders fully stroke to the left, a limit valve pilot-shifts the directional control valve to stroke the cylinders to the right. When the cylinders stroke to the right, the opposite check valves take in and discharge air. Reciprocation continues until outlet pressure from the 3.0-in. cylinder reaches approximately twice the inlet pressure at the 4.0-in. bore cylinder.

The piping arrangement in Figure 13-30 produces less intensified air per compressor horsepower than the circuits in Figures 13-31 and 13-32. Taking in and compressing atmospheric air to a higher pressure gives a minimal high-pressure volume for each stroke. When compressing a gas, reducing volume by one half doubles absolute pressure. If the 3-in. bore cylinder has a 6-in. stroke and intake pressure is 14 psia, then as the cylinder moves through 3 in. of stroke, pressure climbs to 28 psia. As the 3-in. bore cylinder continues to stroke, pressure goes to 56 psia 1.5 in. from the end and to 112 psia 0.75 in. from the end. The cylinder finally starts discharging 160-psia air about 0.625 in. from the end of its stroke. Volume entering the high-pressure receiver is minimal for each stroke, and continues to decrease as the pressure level increases.

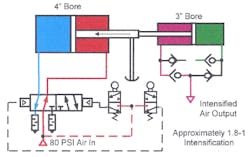

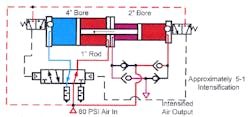

Using shop-air pressure in the intensifying cylinder, Figures 13-31 and -32, greatly reduces this high-pressure/low-flow problem. First, the high-pressure receiver starts with 80 psig and the air in the intensifying cylinder starts at 94 psia. This circuit discharges intensified air for more than half its stroke, making it a smaller, more-efficient package.

Notice also, the approximately 2:1 intensification from a 4-in. cylinder driving a 4-in. cylinder. This is possible because two areas, pressurized by shop air, push against one area of the intensifier cylinder. The actual intensification of the unit in Figure 13-31 is 2.06:1 when stroking to the left, and 1.93:1 when stroking to the right.

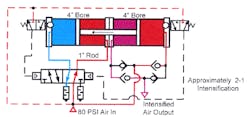

For higher pressure use a smaller-bore intensifier cylinder or a larger-bore driving cylinder. Figure 13-32 depicts a 4-in. bore driving cylinder and a 2-in. bore intensifier cylinder. This combination increases inlet air pressure about five times. The actual intensification ratios are 6.33:1 as the cylinders stroke left, and 4.74:1 as the cylinders stroke right.

When specifying cylinders to build an air-to-air intensifier, be careful not exceed their pressure rating. Pre-lubed cylinders are best for this type of operation because they keep excess lubricator oil out of the high-pressure circuit.

As an air-to-air intensifier pumps air to a maximum pressure, the volume decreases as the pressure increases. It is best to operate the intensifier to produce a pressure 15 to 20% higher than the system needs, with a regulator to set the maximum pressure at the work.