Electrical and electronic devices, such as relay logic circuits, programmable controllers, or computers, normally control fluid power circuits. Fluid power systems can also 0be controlled with "Air Logic." These controls perform any function normally handled by relays, pressure or vacuum switches, time delays, counters, and limit switches. While the circuitry is similar, compressed air is the control medium instead of electrical current.

Environments high in dust or moisture are excellent places for air logic controls because practically no danger from explosion or electrical shock is possible even in these atmospheres. Water can splash on the controls with no effect on the operation. If there is danger of explosion, air controls can not ignite the materials involved.

Air logic can also be used on machines that have cylinders or fluid motors, but no type of electrical device. In such instances, two services are required because the machine is powered by air but controlled electrically. In cases where electrical and mechanical maintenance come under different labor grades, air logic is also ideal because different technicians work on different aspects of the machine -- one works on the circuit and the other handles the machine parts that are electrically driven.

Air logic does have its disadvantages; most common is the lack of understanding of how the components work and how to read the schematic drawing. If an air controlled machine fails, very few persons can work on it. Also, air logic with long control lines will have a noticeably slower cycle. Control lines longer than 10 to 15 ft fill and exhaust slowly when compared to electrical signals. In addition, air quality must be above average for long life.

Air logic controls are basically miniaturized 3- and 4-way air valves. The actions of the valves provide on or off functions like relays or switches. They also exhaust the spent signal. The symbols used for air logic are similar to electronic symbols. Some manufacturers use modified electrical symbols and ladder diagrams to show circuitry.

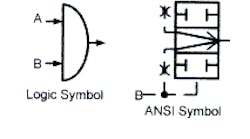

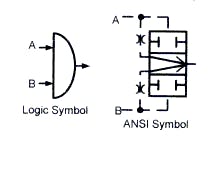

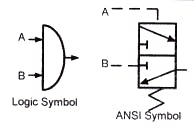

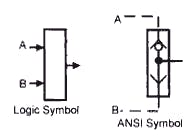

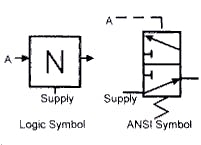

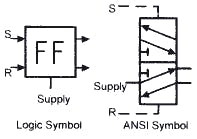

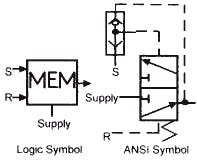

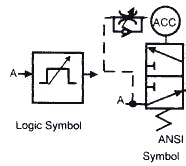

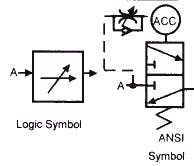

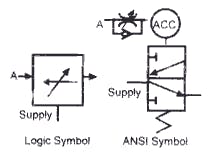

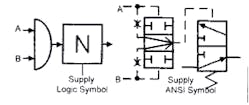

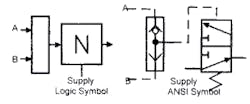

The following is an explanation of the basic logic components showing the ANSI logic symbol and ISO graphic symbol for a comparable directional control valve.

Figures 2-1 and 2-2 show two types of "and" elements, which must receive two inputs before it provides an output. This ensures that two functions have completed before there is a command to continue the cycle. This can also be described by saying "this input, this input, and that input must be present before getting an output. Connect "and" inputs in a series when using more than two inputs. The first "and" receives signals’ one and two while the output of this element hooks to one input of the second "and." The other input of the second "and" receives the third signal, making three inputs necessary before giving an output.

Figure 2-3 shows the symbol for an "or" element. A shuttle valve serves the same purpose as an "or" element. Both inputs to an "or" element provide an output. A pilot signal from two different sources can pass through to start the next function. This can also be described by saying this signal or that signal provides an output. An "or" element differs from an inline "tee" because an "or" passes either input to the output but does not allow the inputs to pass to eachother.

Stacking "or" elements allows for more than two inputs. Use an extra "or" element for each input after the first two signals.

Figure 2-4 shows the symbol for a "not" element, which is a normally open 3-way valve. An input signal or pressure supply will go through the valve until there is a pilot signal at port A. Pressurizing port A blocks supply and exhausts the output signal to atmosphere. "Not" elements will block a signal or supply as long as there is pilot pressure on the A port. The "not" always returns to a normally open condition without a pilot signal.

Replace a limit switch with a "not" element to indicate a cylinder is at the end of stroke. Pressure from the cylinder port goes to port A of the "not" element, holding it closed. As the cylinder moves to the work, pressure stays steady because of the meter-out flow control. When the cylinder contacts the work, the signal on port A drops, the "not" element opens and sends a signal to start the next operation. See Figure 2-21 and accompanying text to review a circuit using "not" elements to replace limit valves.

The cylinder can stop at any position and the "not" output signal will indicate its nonmovement. This will always happen whether the cylinder stopped where it should have or if it stalled by some other means. Because this can happen, take care when using a "not" element to replace a limit switch. In contrast, this feature can be advantageous when clamping different sized parts. Use a "not" element for applications where different work locations stop the cylinder.

Most manufacturers supply a different pilot ratio for a "not" element used as a limit switch. The valve function is the same but it shifts at much lower pressure. Some manufacturers make a special "not" element that mounts directly to a cylinder port. A port-mounted meter-out flow control used in conjunction with this special "not" element makes a compact installation.

Caution! Pressure control valves only show pressure buildup. When a positive location must be made, use limit valves.

Flip-flop circuits

"Flip flop" elements, with their symbol shown in Figure 2-5 are double piloted 5-way valves that send supply air to either outlet port with a signal at pilot ports S or R. Supply can be system pressure or air from another logic element. The main use for a "flip flop" is to eliminate the first pilot signal to a directional control valve. This allows a second signal on the directional valve’s opposite pilot port to shift it back. "Flip flops," sometimes called "memory" elements, stay in their last shifted position even with no air supply. Whether the signal maintains or drops out, output from the "flip flop" stays the same.

The S and R signals stand for "set" and "reset." The "set" signal shifts the "flip flop" for a function; whether the signal continues or not, the element stays shifted. The "reset" signal returns the "flip flop" back to its original position until the next cycle.

"Flip flop" can also be used to set up a new cycle, allowing the operator to momentarily push the start buttons. Use this same "flip flop" to eliminate unwanted signals and set up the circuit for cycle completion as required.

There are three different types of time delays in air logic control. Fixed- or adjustable-time delays are common in both normally closed and normally open configurations. Some time delays use an orifice and accumulator chamber for delays up to one minute. Some manufacturers use air actuated diaphragms and orifices that eliminate system pressure fluctuation inaccuracies.

A "one-shot" timer, shown in Figure 2-7, is sometimes called an "impulse timer." A "one shot" timer takes a signal and passes it on to the circuit. At the same time, the input signal goes through an orifice to an accumulator tank. The setting of the orifice and size of the accumulator give a certain time delay before the normally open 3-way valve closes. After a "one shot" times out and closes, it remains closed as long as it has an input signal.

Figure 2-7 shows an adjustable time delay before it loses its output. Leaving off the sloping arrow in the symbols makes it a preset time delay. Times range from to 2 or more sec on valves with preset time delays.

Many circuits uses "one shots" to eliminate opposing signals. When a valve receives a signal to extend to a cylinder, it resists a return pilot signal to itself until loss of the first pilot. Using a "one shot" element drops the extend signal shortly after iniatiation. However, when the short duratoinj signal meets a hard-to-shift valve, the time may not always be long enough to move the valve spool. The cycle will stall if the valve does not have time to shift. For best results, use a "flip flop" to drop unwanted signals after it performs a task. Figures 2-17 to 2-20 and accompanying text further describe "flip flop" valves.

Passing a signal through the element after timing stops is done with an adjustable, normally closed "time-on" time delay. Figure 2-8 shows the symbol for this element. A "time-on" delay is a preset fixed timer without the sloping arrow. Most anti-tie down circuits use a fixed time delay, thus forcing the operator to actuate both palmbuttons concurrently.

The symbol in Figure 2-8 shows an input A moving towards the blocked port of a 3-way directional valve. Signal A also moves to a meter-in flow control to fill an accumulator. After the accumulator is filled, pilot pressure shifts the 3-way valve, allowing air to pass on to the next operation. As long as the input signal stays on the time delay stays open.

Some brand of "time-on" delays use shop air to the normally closed port A of the 3-way valve while the signal to the timing section comes from another logic element or limit valve. This allows a strong passing signal to travel long distances or to quickly shift several other logic elements.

With a built-in accumulator tank, the time delay length is usually unjer one-to-one and one-half minutes. With added external accumulators, time delays up to 5 min are possible. The repeatability of long time delays using accumulators is poor. Often, diaphragm type timers go to 3 min with good repeatability.

With a normally open 3-way valve in place of a normally closed 3-way, the delay is "time off." Figure 2-9 shows the symbol for a "time off" delay timer. A continuous input to the supply gives an output until a set time after receiving a signal at A. When A receives a signal, the time delay starts and continues timing. When the accumulator fills, it closes the normally open 3-way valve and exhausts the signal. As before, a preset, non-adjustable time delay is available.

"Time-on" and "time-off" delays often are identical in appearance. The part number may be the only way to tell these units apart.

To get different functions, connect air logic elements together like the examples in Figures 2-10 and 2-11. These two common pairs might be familiar to anyone using air logic. A "nand" element, shown in Figure 2-10, uses an "and" to signal a "not." The term "nand" means "not this and this." As long as there are not signals at A and B, air passes. If signals A and B are present, the "not" closes and exhausts the output signal.

A "nor" element, shown in Figure 2-11, uses an "or" to signal a "not." The term "nor" means not this or this. As long as there is not a signal at A or B, air passes through the "not." If a signal is present at either A or B), the "not closes and exhausts the output signal.

Some other commonly used air logic elements include:

- Amplifiers to detect a low pressure signal (down to 3-in. water column) and send it on as an 80 psi signal.

- Pressure or vacuum sequence elements shift after reaching a set pressure or vacuum.

- Programmable controllers are combination elements that are used to design complex circuits with minimum knowledge of circuit design.

- Air-operated indicators show circuit condition and/or function. Several colors are available but none emit light.

The following text and images depict examples of air logic circuits, showing how some basic circuits perform machine control functions.

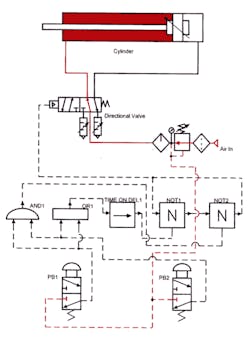

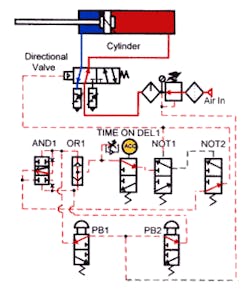

Anti-tie down air logic circuit, using logic symbols

The two-hand, anti-tie down circuit schematic in Figure 2-12 uses ANSI air logic symbols to simplify schematic drawings. However, most mechanics do not understand the hardware behind the symbols. An electrician may recognize the symbols but often does not understand how air logic functions. So like most problems with hydraulics and pneumatics, changing parts, turning knobs, and swapping lines continues until the machine starts working or an expert is called.

To make the cylinder in Figure 2-12 extend, depress both palm buttons at the same time and hold them shifted. Tying either palm button more than one second before actuating the second palm button keeps the cylinder from moving. Depressing the second palm button within one second after the first palm button makes the cylinder extend and stay. Letting up on either or both of the palm buttons causes the cylinder to retract. This means that if the operator tries to use one of his hands to adjust or hold a part, the cylinder retracts. To start another cycle, release both palm buttons to reset the time delay. Both of the operator’s hands must stay on the palm buttons when the cylinder is extending.

Notice that the AND1 and OR1 elements on the left receive signals from the palm buttons at the same time. AND1 uses both signals to get an output while ORr1 gives an output when depressing either palm button.

Actuating palm button PB2 sends a signal through OR1 to start TIME ON DEL1. After approximately one half to one second, TIME ON DEL1 opens, sending a signal through normally open NOT1 to close normally open NOT2. Depressing PB1 after NOT2 closes gives an AND1 output, but it cannot go through to shift the directional valve. Actuating either palm button separately blocks the signal to shift the directional valve at PB2.

Shifting both palm buttons concurrently sends a signal through OR1 starting TIME ON DEL1. At the same time, an output from AND1 passes through NOT2, shifting the directional valve to extend the cylinder. The output ofNOT2 also closes NOT1, blocking the output from TIME ON DEL1. Depressing and holding both palm buttons extends the cylinder and keeps it there.

Releasing one palm button while the cylinder is extending drops one output of AND1. When AND1 drops out, the directional valve spring returns, the cylinder retracts, NOT1 opens, and TIME ON DEL1 output closes NOT2. Depressing the released palm button again leaves the cylinder retracted because TIME ON DEL1 closes NOT2. To start another cycle, release both palm buttons to reset TIME ON DEL1. Figure 2-13 shows this operation using ISO valve symbols.

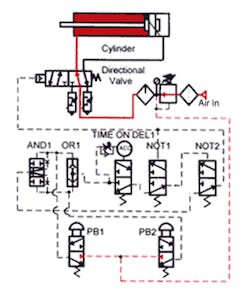

Anti-tie down air logic circuit, using ISO symbols

Figures 2-13 to 2-16 show the previous anti-tie down circuit in ISO symbols. Most people understand ISO symbols since they show valve function more clearly.

The circuit is at rest in Figure 2-13. PB1 and PB2 are not actuated, so there is no signal being sent to the directional valve. This schematic is what the machine supplier sends with his documentation for the machine.

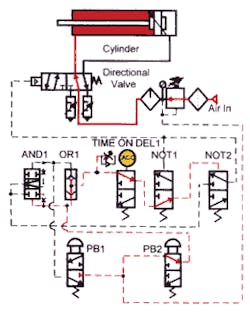

Depressing both palm buttons simultaneously gives the results shown in Figure 2-15. Either one of the signals to the or element starts TIME ON DEL 1but one of the signals to the and element passes through NOT2, on to the directional valve. The signal from NOT2 also pilots NOT1 closed, blocking the output from TIME ON DEL 1. As long as both buttons stay shifted, the cylinder extends and holds.

After TIME ON DEL 1times out, the circuit changes to the one shown in Figure 2-16. Output from TIME ON DEL 1L1 stops at NOT1 because the start signal from the and element is holding it closed. With this circuit the operator has to keep both hands on the palm buttons to make the cylinder extend.

The following circuits show other uses for these elements and how more complex circuits use other logic valves.

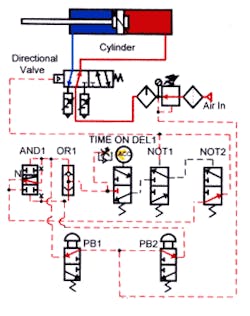

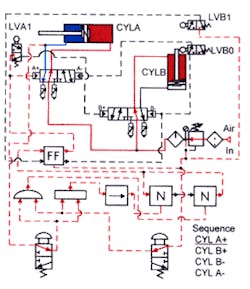

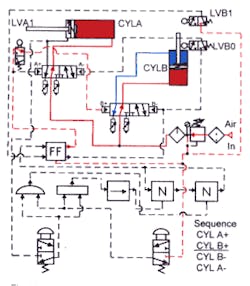

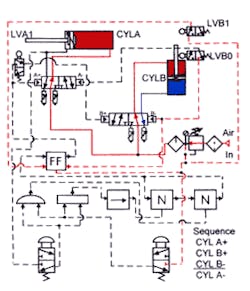

Anti-tie down, non-repeat, flip flop air logic circuit

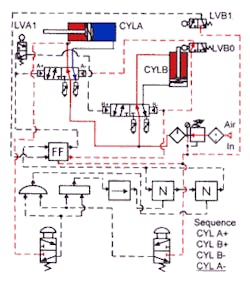

Figures 2-17 through 2-20 show a two cylinder circuit with CYLA extending (A+, CYLB extending (B+), CYLB retracting (B-), and CYLA retracting (A-).

Notice CYLB retracts immediately after extending, which means there would be an extend signal opposing a retract signal if the circuit only has limit valves for control. Using a "one shot" valve to stop the opposing signal works, but is less reliable than the "flip flop," FF circuit shown here.

Figure 2-17 shows both palm buttons depressed, causing the output of the anti-tie down circuit (see the previous explanation of an anti-tie down circuit) to shift FF. The output of the top port of FF sends a signal to shift a doubled pilot valve and extend CYLA. The FF output will also supply the normally closed port of limit valve LVA1. Shifting the FF also drops the signal from limit valve LVB0 that retracted CYLA. CYLA extends until it contacts limit valve LVA1.

When CYLA contacts LVA1, Figure 2-18, air from the top port of FF passes through it and shifts a double piloted valve making CYLB extend. The signal to retract CYLB came from the bottom port of FF that is now exhausting to atmosphere. CYLB continues to extend until it contacts limit valve LVB1.

The normally closed inlet port of LVB1 has a constant air supply, so when CYLB contacts it, Figure 2-19, it shifts FF back to starting position. A signal from the bottom port of the FF shifts a double-piloted valve to retract CYLB and supplies air to the normally closed port of limit valve LVB0. After FF shifts back to the starting condition, it drops the extend signals to both double piloted directional valves. This makes it possible to shift the double-piloted valves to retract the cylinders. CYLB continues to retract until it contacts LVB0.

A signal from LVB0 shifts the double-piloted valve to retract CYLA as shown in Figure 2-20. This cylinder can retract since its extend signal dropped out when FF shifted from LVB0. CYLA retracts to home position and ends the cycle.

The nonrepeat feature is possible because when the circuit is in the at rest position, there is a supply to the left palm button from the rod end port of CYLA. After the cycle starts and CYLA reaches the end of its stroke, the left palm button loses its supply. Whether the operator lets off the palm buttons or not, loss of air to the left palm button disables the anti-tie down circuit.

With both palm buttons supplied with direct shop air, if the operator kept the palm buttons shifted all during the cycle, the machine would probably stall after CYLB extended. The nonrepeat feature adds little cost, but may save lost production.

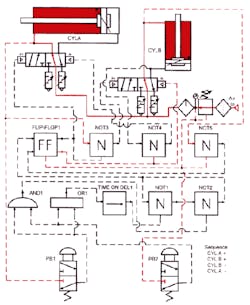

Using modified "not" elements as limit valves

The circuit in Figure 2-21 operates the same as Figures 2-17 through 2-20 on the preceding page. The only difference is pressure controlled "not" elements replace limit valves.

"Not" elements can replace limit valves when the movement they are detecting is not critical. "Not" limits operate any time the cylinder has a pressure drop. The pressure drop could be end of stroke or any place the cylinder stops for any reason. If actuator position is critical, always use limit valves.

Using a standard "not" to replace limit valves works, but the special low pressure "not" is best. Some manufacturers call this an "inhibitor", others, a "pressure trip release." Whatever the name, the modification causes the valve to shift at a lower differential pressure. This keeps a reduced backpressure at the cylinder port from giving a premature signal.

Using "not" elements in place of limit valves makes installation and plumbing easier, but can make troubleshooting more difficult. Placing the "not" elements in the control box works, but cylinder port mounting is best. No matter the location, they must read the air between the cylinder port and a meter-out flow control. This location ensures they see backpressure when the cylinder is moving.

Because a "not" is normally open, pressure holding the cylinder in position and backpressure from a meter-out flow control when the cylinder is moving give the signal to hold it shut. When the cylinder stops, pressure drops, allowing the "not" to open and send a signal to continue the cycle.

The circuit in Figure 2-21 uses "not3" to tell CYLB to extend, "not5" to tell CYLB to retract, and "not4" to tell CYLA to retract.

Since the "not" works on loss of pressure, a cylinder with leaking seals can keep it from shifting. After a slowly moving cylinder stops, slow deterioration of pressure may delay the output signal.

Loss pressure valves have many benefits. For example, it does not matter when the cylinder contacts the part. Whether the part is 1 or 20 in. thick, when the cylinder makes contact, there will be an indication. In addition, air pressure changes have little or no effect on them as the "not" only reads minimum pressure. Finally, maximum pressure setting does not affect a "not" like it does a sequence valve. "Not" elements are a preferred choice over sequence valves because sequence valves only work with meter-in flow controls. Any air cylinder has better control with a meter-out circuit and overrunning loads require meter-out flow control.

Always use loss of pressure controls with caution since they can operate any time cylinder pressure drops below their minimum shifting pressure.

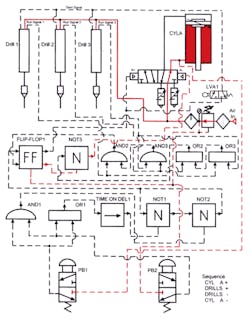

Anti-tie down, non-repeat and flip flop air logic circuit with automatic cycling air drills

Figure 2-22 shows a clamp cylinder, CYLA, and three self-contained automatic air powered drills controlled with air logic.

Some circuits clamp a part then start the drills with a "one shot" element. As long as all the drills start there is no problem. However, if any drill fails to cycle, parts may come off the fixture with one or more holes missing. When double drilling is necessary, part costs’ and scrap increase. The circuit in Figure 2-22 eliminates this problem with air logic elements and piping.

When the anti-tie down circuit shifts "flip flop" FF, a signal from its top port goes to extend clamp cylinder CYLA. FF top port output also supplies the normally closed port of limit valve LVA1. CYLA extends, clamps the part, and shifts limit valve LVA1. Use a limit valve here since the drills could sling a loosely clamped part out of the fixture. A pressure operated "not" circuit could allow premature cycling of the drills, resulting in damage and safety concerns.

After clamping the part, FF output goes through limit valve LVA1 to the drills’ start ports. When the drills start they give a run signal when they move from home position. This run signal remains on until the drills fully retract. On most of these types of air-operated drills, the output is the same air that turns the air motor in the drill. One brand of air drill has an output when at rest and exhausts that signal when it starts.

The drill run signals go to the input ports of two "ands" and two "ors". When the two cascaded "ands" have three signals indicating all the drills are moving, their output shifts FF back to its starting position and exhausts the drill start signal. The three inputs to the two cascaded "ors" pass through to close "not3" so the clamp will not open until all drills have retracted. Output from the lower port of FF goes to the inlet of "not3" to set up clamp CYLA open sequence.

The drills will continue forward until they meet their internal limit valves and retract. The run signals drop out as each drill finishes and retracts to home position. When the last drill is home, the run signal from the last "or" element exhausts and "not3" opens. When "not3" opens, its output shifts the clamp valve to retract CYLA.

If starting of one of the drills is sluggish, the run start signal stays on until it moves. If a drill fails to start, the run signal stays on and the running drill stay extended. In either case, the operator knows when a problem exists. If one of the drills hangs in the part, the clamp will not open until the drill is free to retract. For every added drill, use another "and" and "or" element. With air indicators installed in each drill run signal line, picking out a nonrunning drill is easy.