Moving parts in fluid power systems are subject to wear from contamination. Neither atmospheric air nor hydraulic fluids are clean enough as supplied to avoid this and they both become more contaminated with use. Therefore all fluid power systems require filters to remove contamination and thereby increase component life.

Pneumatic filters and lubricators

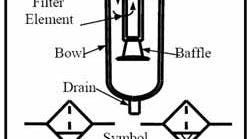

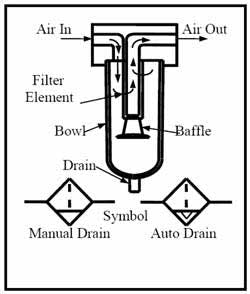

A pneumatic filter should be the first component at the inlet of most air circuits. This unit usually is one part of a combination of components that filters the air, regulates its pressure, and adds lubricants for moving parts in the circuit. The air filter and lubricator are covered in this section. (An air line regulator performs the same function as a hydraulic reducing valve and is covered in that section.)

Air from the compressor contains dust from the ambient atmosphere, condensed water, and rust and oil sludge that bypass the compressor rings. These by-products of compressing and transmitting air must be removed to keep moving parts of the machine working properly. Most filters clean the air and separate condensed water from it before the air enters the circuit.

The coalescing filter shown in Figure 7-2 removes water and oil vapors as well as condensed moisture from an air line. To accomplish this, coalescing filters are not only designed differently but they have reverse flow in relation to a standard filter. These filters will remove particles as small as 0.3 to 0.6 µ. They use a coarse mat of very fine fibers that are small enough to catch and hold these very fine particles. As the vapor collects into droplets, they are channeled to the quiet zone and drained.

must be applied according to manufacturers’ specification to keep collected liquid from being re-entrained into the air stream. Also, always make sure the flow direction is according to information on the filter housing. Several companies make these high-efficiency air filters though they are not often applied to every day circuits.

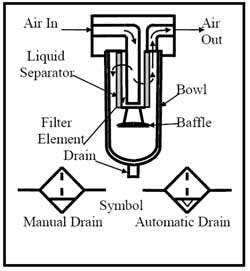

Figure 7-3 shows a cutaway view of an air-line lubricator. After the combination unit filters and regulates air pressure, some downstream system components may require a small amount of lubrication. (For example: air motors are one item that needs a constant supply of oil to extend their life and maintain torque.) Some cylinders are pre-lubed and most valves require little if any lubrication, so keep oil supply to these units at minimum. A general rule: a ½-pint bowl of oil in a lubricator should last three weeks to a month in most situations.

Air line lubricators are designed to send a mist of oil to the parts in the downstream circuit. However, the physical size of some circuits makes it impossible for the mist to stay in suspension long enough to reach some parts. In this case -- and for some air motor applications -- it is necessary to inject oil at the components inlet. There are electric and air-driven lubrication units to meet the needs of these applications.

Compressed-air dryers

Why are air dryers necessary? All air compressors take in atmospheric and compress it eight or ten times to a pressure between 110 and 125 psig. All the moisture vapor and heat in the atmospheric air is also compressed and concentrated, so air at the compressor outlet is hot and wet. The temperature of the air at the compressor outlet can be as high as 350ºF. The air also can be saturated with water vapor. As this air cools in the receiver and plant piping, the water vapor in it condenses into water droplets.

A 25-hp compressor running at 75% capacity pumps 18 gallons of water into a plant air system on a day with average ambient humidity. An aftercooler condenses and removes about 11 gallons of this liquid, but that still leaves 7 gallons to collect in low spots, retard valve movement, damage production parts, and cause problems in general.

Types of air dryers

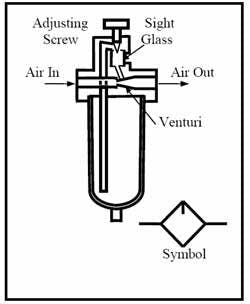

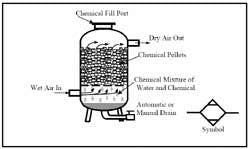

Figure 7-4 shows a cutaway view of (and the symbol for) a deliquescent air dryer. Wet air enters the dryer (which is a pressure vessel), passes up through a bed of hygroscopic chemicals, and flows on to the outlet. The chemicals (often a form of sodium) absorb moisture from the air as it passes through the bed. As they dry the air, the chemicals break down into a slurry of water and chemical drops that falls to the bottom of the tank. A manual or automatic drain keeps the water mixture from rising too high and mixing with inlet air flow.

A typical deliquescent dryer removes moisture to a dew point of about 40ºF. Air that has passed through this dryer must be cooled below 40ºF before any more moisture will condense. This dew point is satisfactory for most plants -- even during winter cold. However, the hotter the air passing through the chemicals, the less the amount of moisture the chemicals will collect. Thus it is important to keep the incoming air at or below 100ºF. This usually requires an upstream aftercooler to lower the temperature of the air being delivered from the compressor. Air at higher temperatures at the inlet results in higher dew points at the outlet.

Deliquescent dryers are the least expensive of the three types mentioned in this section, but they might cause problems in some installations. There is always a chance of the chemicals or their vapors being picked up by the air stream and sent into the pneumatic system. These chemicals are corrosive and can damage internal parts. Also chemicals must be replenished on a regular basis. This means shutting down the compressor or bypassing the dryer when chemicals get low. Finally, slurry must be removed.

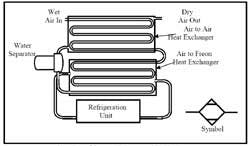

To keep operating cost down these systems usually have an upstream water-cooled aftercooler to cool compressor air and take out the bulk of the moisture. Normally a maximum incoming temperature of 100ºF is recommended. When a higher inbound temperature is present, oversize the refrigerated dryer to handle the extra energy removal. (Of course, this adds extra cost to the purchase of the unit, as well as increasing operating cost over the life of the system.)

Wet air enters the unit through an internal air-to-air heat exchanger. This unit is piped to pre-cool the hot inbound air and re-warm the cold dry air before it exits the dryer to enter the plant piping. This arrangement saves energy by removing some of the heat in the incoming air. It also keeps the plant piping from condensing water vapor from ambient air on its cold exterior surfaces and dripping water on the production floor.

The pre-cooled air then passes through a Freon-to-air heat exchanger that reduces its temperature to approximately 35ºF. This procedure condenses more water vapor to achieve a 35ºF dew. If plant temperature stays above 35ºF (as it does in most plants), there will be no more condensation inside the air piping. The condensed water drains from the dryer through a water separator.

The main potential problem with refrigerated dryers is they will freeze up if temperature is set too low or if the amount of air passing through them is low and intermittent.

Another approach to refrigerated drying is drying the air before it enters the compressor. One company offers chillers that take atmospheric air down to –40ºF. and feed it to the compressor. After it is compressed to 100 psi, the air has a pressure dew point of approximately 35ºF. Because the compressor takes in air that is denser and at such a low temperature, the heat of compression is negligible. Also, most of the airborne contaminants are removed during the cooling, condensing, and freezing process. These inlet air dryers use dual refrigeration units. While one is drying input air, the wasted heat from the drying unit defrosts the other.

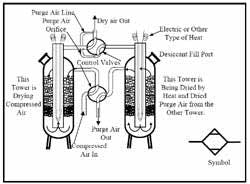

Figure 7-6 pictures a twin-tank desiccant dryer that uses a hygroscopic material (such as silica gel or activated alumina) that collects water vapor but is not broken down by it. This type dryer is called an adsorber because it collects water vapor but once the moisture is removed by heat or other methods, the chemical is ready to work again. This desiccant dryer may achieve dew points of –40ºF or lower, so the air can be used in most outdoor circuits without fear of freeze ups.

As wet compressed air enters the control valve, it is channeled to one of the desiccant tanks. (The control valves are usually set up to shift automatically, triggered by a signal from a device that monitors the output air’s dew point.) Wet air is forced through the desiccant material to take out water vapor, then sent on to the plant. Some of the dried air is diverted through an orifice to the spent tank, where it is heated and then passed through the wet desiccant in the other tank. Water again vaporizes and exhausts to atmosphere. This drying process continues at the rate necessary to maintain the required dew point.

Desiccant dryers are the most expensive type to operate and maintain. In particular, they are subject to failure if the incoming air contains carry-over compressor oil. The oil can coat the desiccant and make it incapable of collecting moisture. The main expense of operating these dryers is the energy used to dry out the idle tank of desiccant.

Hydraulic filters

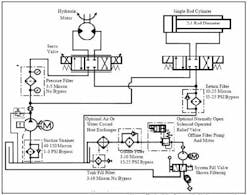

In Figure 7-7, a schematic drawing of a hydraulic circuit shows filters in the standard locations, with typical filtration ratings listed next to them. Note that most circuits would not have all of these filters, but every circuit should have adequate filtration to protect the pump, valves, and actuators from contamination.

There are several sources of contamination in and around hydraulic units. Normal component wear, contamination in new oil, sloppy filling practices, poor plumbing installation, and dirt carried in on piston rods are the main ones. Some of these areas are simple to address ahead of time, while others can only be handled by filtration.

New oil from the supplier is not as clean as most hydraulic circuits require. At best about 25-µ cleanliness is all most suppliers will offer. One reason: the drums that new oil comes in probably were used before. Although they were cleaned, they are not contaminant-free. In addition, a standard drum pump draws fluid from the bottom of the drum where all the residue has settled.

Figure 7-8 shows a manually operated 3-way valve installed in the suction line of an offline filter pump. When this valve is shifted, all new fluid has to go through the offline filter before it enters the tank.

Another item in Figure 7-8 is a tank-fill filter with no bypass, which filters all new oil entering the tank. Another option is to use a purchased filter cart to fill the tank through its normal fill port.

Whatever the method, it is important to keep filling practices from introducing contamination. While the fill port offers one of the simplest places to address contamination problems, it often is overlooked.

Another way that contamination enters a hydraulic circuit – even before startup -- is through poor plumbing practices. All pipe, tube, and hoses should be inspected for contamination before installation and cleaned if necessary. It’s good practice to seal clean conductors with caps until installation time. Use care when cutting and preparing pipe or tube ends to make sure no metal chips or filings stay in the conduits. If the system includes servovalves, flush it with filtered oil through flushing covers for the time recommended by the valve manufacturer before startup. Use every possible precaution on a new or replacement plumbing system to make startup go smoothly.

In a running circuit, one of the most common sources of ingressed contamination is the cylinder piston rods. Every time a piston rod extends, it is damp with system oil. In a dusty atmosphere this oil-dampened piston rod attracts and holds fine particles. Many of these are dragged back into the cylinder and washed off. Most cylinders have a rod wiper to help keep out contamination but this wiper only catches large pieces. Everything smaller passes by. This type contamination must be filtered out continuously to protect system components. Some suggest flexible boots or bellows over the rod end of the cylinder to eliminate rod contamination ingression. A flexible bellows does a good job unless it gets a tear or other type hole. At this point it actually sucks in ambient air with its contamination and holds it closely to the rod.

A similar situation takes place at the tank breather. During each cycle, the fluid level in the reservoir changes -- either drawing dirty atmospheric air in or discharging air through the breather. The filler breather should be capable of trapping the inbound contaminants in this air flow.

The other main cause of contamination is normal component wear. Dynamic pumps, motors, and cylinders have constantly rubbing metal-to-metal contact areas. Even with good lubrication, small eroded particles get into the fluid. This contamination must be constantly captured by filters to eliminate a damaging buildup of residue.

Condensed water is another form of contaminant that should be addressed. Water in hydraulic fluid can cause corrosion, break down fluid additives, and make viscosity vary. Water vapor often enters the system through the breather and condenses to liquid form when the tank cools. Using a breather with a hygroscopic media can eliminate most water contamination. Most of these hygroscopic breathers must be changed when they become saturated. They often use silica gel that is blue tinted when dry and turns a pink tint as it gets wet, signaling that a change is needed.

Cleanliness levels

The circles in Figure 7-7 indicate relative sizes of contamination particles. Not all contamination is nice round marble like pieces as the two overlaid examples show. Particle size is measured by enclosing it in a circle until it touches at two or more places. The 150-micron (150-µ) particle may only be 20 to 25 µ thick but is considered 150 µ because of its length.

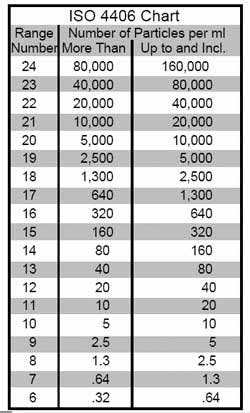

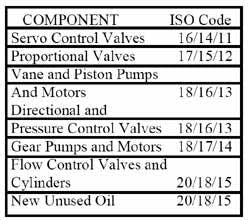

ISO has set up cleanliness level standards for hydraulic and lubrication fluids. The system most used for hydraulics is based on the ISO 4406 standard. This standard covers the number of particles of a given size that can be present in a fluid sample in three different micron ranges. It is designated ISO Code XXX/XXX/XXX, where the numbers relate to the minimum and maximum number of particles of a given size that can be present in a 100 milliliter sample. The first number indicates how many particles of 2-µ size can be present; the second number is for 5-µ particles; and the third number is for 15-µ particles. It might be written ISO Code 18/16/13. The numerals always descend in value from left to right. This code would mean that there could be between 1300 and 2500 particles of 2-µ size, 320 to 640 particles of 5-µ size, and 40 to 80 particles of 25 µ.

Figure 7-7 indicates that, even with good eyesight, people cannot see a particle smaller than 40µ. Thus it is impossible to look at a sample of fluid and determine whether it is clean. Of course, it is possible to tell it is contaminated when large particles are plainly visible in the sample.

The ISO 4406 chart shows the range number and the number of particles that it represents. From this chart it is easy to set up or pick out any ISO Code cleanliness level.

Some typical fluid cleanliness level ISO Code’s are shown in the following chart:

Beta ratios

Another rating applied to hydraulic filters is the Beta ratio (also known as the Filtration ratio). It is a measure of the particle-capture efficiency of a filter element. The ISO 4572 Multipass Test passes fluid through the circuit shown in Figure 7-7 to check for contaminant retention. A measured amount of contaminant is injected upstream of the filter. Laser particle counters record the number of particles into and out of the filter. When 100,000 particles are measured upstream of a 10-µ filter and 10,000 downstream, it would have a Beta ratio of 10 (100,000/10,000 = 10).

A Beta Ratio number is of no use alone, but it is required to find the filter’s efficiency rating. Efficiency of a filter element is what counts when comparing one filter to another. The higher the efficiency, the fewer contaminants will pass through it. Efficiency coupled with the volume of contaminant retention can make a more expensive filter cost less due to its longer useful life.

Efficiency is calculated by the formula:

Efficiency10 = (1–1/10) X 100

Efficiency10 = (0.9) X 100

Efficiency10 = 90%

Always make sure the filter meets or exceeds the desired cleanliness level of the system it is protecting.

Filter locations

Figure 7-8 shows most of the locations where filters might be found in any hydraulic circuit. Note that all of these filters are seldom found in a single circuit but some circuits might have filters in two places. Two other types of filtration -- off-line and filter fill -- also are shown in Figure 7-8. Any of these filters could be the dual, change-on-the-run type when required. Dual filters are more expensive but can reduce downtime.

Suction strainers

A suction strainer (as shown at the lower left in Figure 7-8) often is found on the pump inlet line. Strainer is a common term for filters with openings of 75 m1 or larger. Strainers on the pump inlet line protect the pump from large, damaging contaminant particles that could cause catastrophic failure. These particles might be startup debris left in the tank and piping or large contamination introduced to the system from external sources or from internal part failure.

Pumps without supercharged inlets can only tolerate a portion of one atmosphere pressure drop without affecting inlet flow. With this low pressure drop, (14.7 psi maximum at sea level on an average day), a restriction such as a low-micron filter can cause the pump to cavitate. Cavitation causes pump failure faster than dirty oil; so avoid it in every situation. (See the write up on pump inlet conditions and cavitation in Chapter 8.)

Suction strainers are available with 75- to 150-µ openings. Some manufacturers have inlet filters with ratings as low as 25µ. A low-micron element needs large filtering surfaces to keep pressure drop low. When a pump is force fed by another pump -- sometimes called a supercharging pump -- a low-micron rated element can be used. The supercharging pump forces fluid through a very fine filter to the working pump, thus keeping it from cavitating.

A suction strainer or filter should have a bypass relief valve. Set the bypass to open at a pressure of 1 to 3 psi if the strainer clogs. The reasoning behind this is that the pump will run many hours on contaminated oil, but will fail in a short time with little or no oil. Suction strainers may be located inside or outside the reservoir. Internal strainers are less expensive, but their condition is more difficult to monitor. External strainers are easy to service and often have an indicator to show when the filter starts bypassing. The indicator can be as simple as a vacuum gauge or it might be a vacuum-operated electrical output to a warning light, alarm, or shut-down controller.

Many older circuits have nothing but a suction strainer for filtration. Retrofitting these systems with off-line or kidney-loop filters (discussed later) is advisable.

Return-line filters

Another common location for filters is in the return line. (Figure 7-8 indicates this location at the right center.). A return-line filter keeps most contamination that is caused by part wear or ingestion from getting into the tank, this protecting the whole system. Return-line filter protection ratings typically range from 3 to 25 µ. Obviously, you should select a return-line filter rated for the desired system-cleanliness level or less.

Return-line filters should have integral bypass check valves. If the filter becomes loaded, return oil needs an open flow path to tank until it is convenient to change the filter. Without a bypass, the filter element probably will collapse, or the element housing or seal may rupture.

Typical bypass checks require 10 to 50 psi to open. The bypass pressure should be high enough to stop fluid from going around the filter during normal conditions, but low enough to avoid damaging filter element and its housing seal.

Some designers size return-line filters just large enough to handle the pump’s rated flow. This can cause problems, especially if cylinders in the circuit have oversized rods, or if one cylinder must return one or more other cylinders. For example, if a cylinder has a 2:1 rod diameter, flow to tank while the cylinder is retracting is double the pump flow. Sizing the filter just for pump flow in this case allows contaminated oil to bypass the filter, and may damage the housing or seals. Paper filters can collapse, have holes blown through the element, stop filtering, and never indicate they need replaced. On pleated elements, the pleats can collapse, giving a “loaded element” indication prematurely.

Even with a correctly sized return-line filter, flow through it changes constantly. Steady flow through the element gives the most efficient filtering. If a filter passes constant flow, the bypass valve will not open until the filter fills with contaminants. This means only clean fluid leaves the filter. Visual and electrical indicators are available to show when a return filter is bypassing.

Pressure filters

Another location for filters is in the pressure line (as shown at the left middle of Figure 7-8). These filters are mandatory in systems using servovalves. Servovalves have low contamination tolerance. They have small internal orifices, very close tolerance fits, and must shift rapidly at low pilot pressure differential. A servovalve can stop functioning in as little as two minutes when supplied with oil that is clean enough for a typical hydraulic system. Even when a 3-µ return-line filter is in place, contamination generated by the pump is enough to shut down a servovalve in a short time. (Note that fluid for a proportional-valve circuit often requires the same cleanliness level as a servovalve circuit to maintain fast response and consistent operation.)

Actually, pressure-line filters would be an added advantage for any hydraulic circuit, but high initial and replacement cost limits their use. Pressure-line filter housings must be strong enough to withstand full system pressure. When there is a high pressure drop across the filter, the element must not collapse. These requirements make filter housings and elements much more expensive than other type filters. Pressure-line filters usually have elements with 1- to 5-µ openings. The pressure-line filter should have an absolute rating, or have a Beta Ratio of 50 or higher. A pressure-line filter should not have a bypass. If the filter element clogs, it is better to stop flow to a servovalve than to contaminate it. Visual and electrical clogging indicators are available for most pressure-line filters. They warn of potential clogging so that elements can be replaced well before production speed is affected.

Off-line filtration

Off-line filtration systems -- sometimes called kidney loops or bypass filters -- consist of a separate pump, motor, and filter circuit that takes oil from the reservoir and re-circulates it. The system pumps oil from one end of the tank, passes it through a filter, and returns it to the opposite end of the tank. Figure 7-8 shows an off-line filtration system at the lower right. This arrangement is a good way to provide high-micron continuous filtration. The systems are easy to retrofit to existing hydraulic circuits and offer an excellent way for new installations to get high cleanliness levels.

Off-line filter circuits are usually rated in the 3- to 10-µ range and should sized to filter the volume of fluid in the reservoir every 1 to 3 hours minimum. This low, constant flow rate makes the filter very efficient, never opens the bypass, never causes media channeling, and never blows holes in the element.

When the filter indicator shows a clogged element in the off-line system, the main hydraulic circuit can continue to operate during filter change. Conversely, this off-line filter system can continue to run when the main hydraulic circuit is off overnight or weekends.

System-fill filters

New oil is not as clean as most hydraulic systems require so it should be filtered before use. To do this, introduce new oil to the tank through a pair of shut off valves, or a 3-way ball valve (as shown in Figure7-8 at the lower right) in the suction line of the off-line filter pump. Rotate the 3-way ball valve 180 degrees, hooking the off-line pump’s suction to a flexible hose from the oil drum or fluid container. This setup filters all oil from the fluid container as it fills the reservoir.

Another way to make sure all fluid is filtered before use is through the use of a tank-fill filter (as shown in Figure 7-8 at the lower middle). Here a low-micron pressure filter is installed in the tank wall and provides the only way to fill it. The filling process can only introduce clean fluid to the reservoir.

Additions to a filter loop

An off-line filter circuit also can provide heating or cooling functions. Figure 7-8 shows a bypass circuit with a normally open solenoid relief valve, a high-horsepower motor, a temperature switch, a heat exchanger, and a temperature-controlled water valve or switch. These additions can effectively control temperature while filtering the fluid. To only filter the oil, leave the water or fan turned off and the solenoid relief valve de-energized (or open).

If oil temperature drops, a temperature switch energizes the solenoid on the relief valve, and pressure rises. All electric motor horsepower converts to heat until the temperature switch indicates correct oil temperature. Unlike an immersion-type electric tank heater, the fluid is being circulated, so there are no hot spots.

For every electric horsepower, there will be 2544 Btu/hour heating capacity. After figuring the Btu/hour to heat or maintain minimum temperature, divide by 2544 to calculate the horsepower needed. (The formula for calculating tank heating appeared in Chapter 6.)

If the tank fluid temperature goes over a preset limit, a temperature-controlled water valve opens to send water through a heat exchanger or a temperature switch turns on the fan of an air-cooled heat exchanger. All filtered flow is cooled when the temperature-control device indicates elevated temperatures.

When installed in an off-line filtration loop, the heat exchanger receives constant flow, so it needs no bypass valve. Also, the heat exchanger sees flow even when the system uses a pressure-compensated pump.

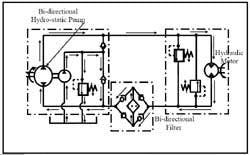

Bidirectional pressure filters

The only difference between a bidirectional pressure filter, Figure 7-9, and a standard pressure filter is the four check valves in the housing. These check valves cause oil flow to pass through filter element in the same direction regardless of the direction fluid enters the housing. Another name for a bidirectional filter is last chance filter. It is installed in a working line to an actuator so it must withstand maximum system pressure. Bidirectional filters with 3- to 10-µ ratings are adequate for most circuits.

Closed-loop hydrostatic transmission circuits are one place to use bidirectional filters. The oil can stay in the loop between the pump and motor for long periods. Any contamination in this closed loop continues to cause damage, even with ample filtering of oil in the tank.