Containing a pressurized fluid between mating surfaces without leakage requires the surfaces to be smooth and flat, and with an appropriate gasket in between. Of course, this is no guarantee of leak-free operation. Gaskets can deteriorate over time, and surfaces can become warped from heat or pitted from corrosion.

After a component has been repaired, it’s always better to find out if it is leaktight before it is put into service. Several instruments are available to evaluate the flatness of surfaces, but these inspections don’t occur when the component is pressurized.

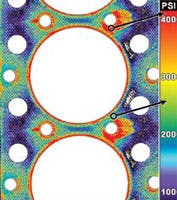

The closest thing to a guarantee may be to use a Pressurex pressure indicating film from Sensor Products Inc., Madison, N.J. Pressurex is a thin flexible film that allows quick and easy determination of compression, magnitude, and distribution between two mating surfaces. And because Pressurex is flexible, surfaces don’t have to be flat — they can be round or contoured.

Pressurex has proven success in assessing surface contact inconsistencies in gaskets, clamps, bolted joints, heat sealing elements, lamination presses, nip rolls, welding heads, clutch and brake assemblies, connectors, and heat sinks. For example, Sensor Products’ Arlene Gleicher cited that one user used Presurex to text the integrity of the crimped union between a hydraulic hose and end fitting.

Pressurex can also be used in manufacturing operations and for machine and component inspection. Placing a sheet of Pressurex between dies of a hydraulic or pneumatic press can show whether or not pressure is applied uniformly to all areas of the dies.

Pressurex film indicates pressure from 2 to 43,200 psi. When placed between two contacting surfaces, the film instantaneously and permanently changes color. This color change correlates directly to the actual pressure applied. Precise pressure magnitude is easily determined by comparing the resultant color to a color correlation chart. The film comes in the form of a thin Mylar sheet, physically similar in thickness to paper, that conforms to curvaceous surfaces and invasive intolerant environments.

For a free sample of Pressurex, contact Sensor Products Inc. at (973) 884-1755 or email [email protected]. More information is also available at www.sensorprod.com/sample.