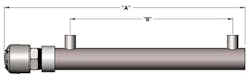

SOLUTION: Install a hydraulic fluid immersion heater into your hydraulic or lube oil reservoir. A low-watt density heater is used to prevent fluid damage. Heater sizing will vary depending on numerous variables. These hydraulic fluid heaters are available with adjustable thermostats allowing the oil to be heated overnight so that you can control your start-up temperature. Weather-resistant terminal enclosures are also available allowing these heaters to be installed on outdoor equipment or in areas where wash down conditions exist.

Hydraulic fluid heaters ensure easy flow

When exposed to cooler temperatures, reservoirs storing hydraulic fluid often need to be heated. Cool hydraulic fluid can suffer from poor flow rates resulting in sluggish performance. To ensure easy flow, Warren Electric Corp.’s hydraulic fluid heaters are used to maintain the fluid at a desired temperature.

Warren Electric Corp. also has the capability to manufacture custom hydraulic fluid heaters to meet your unique application requirements. The Warren Electric Corp. Hydraulic Fluid “Quick Quote” Form is a convenient means to receive sizing and quote assistance. Click here for Hydraulic Fluid Quick Quote.

When determining what size heater is needed for a hydraulic fluid reservoir, variables that are taken into consideration when sizing a hydraulic fluid heater include:

- Volume to be heated

- Dimensions and capacity of tank

- Thickness of insulation on tank (if any)

- Temperature to maintain, worst case ambient temperature and desired heat-up time if tank is allowed to cool during non-operating periods

- Available operating voltage and phase

- Environmental operating conditions to select the proper terminal enclosure

- Desired temperature controls (available with or without thermostat, thermocouple or over-temperature cut out devices)

- Flow rate, desired inlet and outlet temperatures if heater will be used in a casing

Typically, hydraulic fluid heaters have a low watt density, approximately 10-12 WSI. This prevents the fluid and/or the heater from being damaged while heated.

Additional resources

Hydraulic heater catalog link:

http://www.warrenelectriccorp.com/images/br-400.pdf

Quick Quote:

http://www.warrenelectriccorp.com/catalog/hydraulic-heaters/default.asp

Link for thermostats

http://www.warrenelectriccorp.com/products/other-products-accessories/default.asp#temperature-controls

Link for terminal enclosures

http://www.warrenelectriccorp.com/products/specifications-options/terminal-enclosures/default.asp

Link for warrenelectriccorp.com

http://www.warrenelectriccorp.com/

Link for casings

http://www.warrenelectriccorp.com/products/casings-and-assemblies/default.asp