Appeared in print as "Clamping system losing pressure"

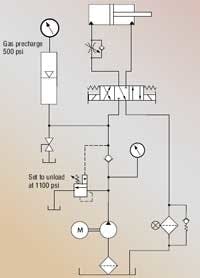

Maintenance checked the gas precharge on all four piston accumulators and confirmed they were all close to 500 psi. They made sure all the accumulator bleed down valves were open and had drained all the hydraulic pressure from the systems.

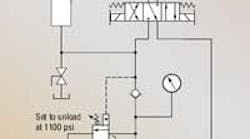

When running and when idle, all four systems would cycle on and off as you would expect with accumulator unloading circuits as shown in the circuit. When pressure reached 1100 psi, the unloading valve would open completely, allowing the pump flow to free-flow back to tank with very little backpressure.

When the accumulator’s hydraulic pressure dropped about 15% to 17%, the unloaded pressure control would snap closed. This forced the pump flow to enter the accumulator circuit until pressure reached 1100 psi, then the pressure control would unload again. The problem circuit seemed to cycle more frequently than the others.

All four cylinders were isolated from the system and checked for internal leaks. One of the cylinders that worked well had a small by-pass, but it did not affect the needed cycle time. They installed flow meters and all four pumps checked out as being in good condition.

Any ideas about the cause of the problem?

Find the solution

Think you know the answer? You can submit solutions by e-mailing [email protected]. We will also post this problem at forums.hydraulicspneumatics.com/groupee, under the Editorial Comments section. Answers can be posted there as well.

All correct solutions will be entered for a chance at a $50 gift card — we will randomly select a winner from all correct answers. The winner will be notified and his or her name will be printed in the August issue.

The correct answer will be published in the next edition of “Troubleshooting Challenge,” and also at forums.hydraulicspneumatics.com/groupee.