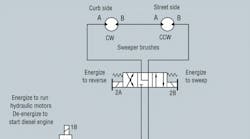

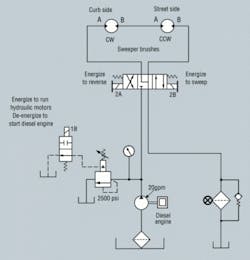

One contractor explained that his sweepers were breaking down frequently due to their hydraulic motor shaft seals failing. The part of the circuit for the brush motors is shown. The motor on the curb side seemed to fail more often than the one on the street side.

A manufacturer’s catalog stated that the sweeper’s hydraulic motor was “especially suited for low-flow, high-pressure applications.” It also stated: “High pressure Viton shaft seals eliminate the need for a case drain.” System pressure in the sweeper’s hydraulic system would fluctuate between 1500 to 2000 psi, and the rated continuous pressure listed in the catalog was 3000 psi. The system relief was set to 2400 psi. The catalog suggested a particular model for bi-directional applications, which was the case for this equipment.

At first, the contractor ordered shaft seal kits, then started ordering new units because he thought his maintenance people might not be installing the seals properly. But failures still occurred.

Any idea why the shaft seals were failing?

Robert J. Sheaf Jr., is founder and president of CFC Industrial Training, a Div. of CFC Solar, which provides technical training, consulting, and field services to any industry using fluid power technology. Visit www.cfc-solar.com for more information.

Solution:

Failing motor shaft seals are usually caused by high pressure or pressure spikes. In addition, dirty oil contaminants can embed themselves in the rubber-like seal material and actually grind a grove in the steel shaft causing excessive clearances and leaks.

The rotation on most hydraulic motors can be reversed by switching the port connection plumbing without resulting in any change in performance. However, several motor manufacturers like Parker and White Hydraulics, ( to name a few), offer motor designs where switching the ports to reverse the motor rotation has limits. For example, White Hydraulics offers a motor that they say is a: “Perfect compromise between price and performance by producing work horse power at a reasonable price.”

These types of motors are fine if the application fits their design. The New Orleans contractor with several pavement sweepers had several motors in stock and was not aware that switching the inlet port plumbing to reverse the motors would cause premature shaft seal failures rotating in one direction and normal life rotating in the opposite direction.

The original circuit called for clockwise and counter-clockwise motors both with the “A” port as the inlet. The physical motors are identical except for an internal plate and one number in the model code. Once the correct arrangement was restored, the shaft seal problem was resolved.

Solution to February’s classified military project faults and leaksThe military project, with the 60-gpm pump and 40-hp electric motor, had two problems. The first was the lack of pressure. A load-sense compensator needs external pilot pressure to function above the original 300-psi load sense spring setting. The pressure needed to move a cylinder is fed to the load-sense spring chamber and is additive to the spring. The control orifice was probably blocked with contaminants, but the pump was still okay because the spring could increase the pressure to its limit of 500 psi. The second problem with the leaking return line filter is a common problem when the return flow from the cap end of the cylinder is intensified due to the area ratio of the cylinder. If you divided the cap-end area by the rod-end area and multiplied the quotient by the pump flow going into the rod side, you would determine the flow leaving the cap end and going through the filter. A 2:1 area cylinder would result in a 120-gpm flow through the directional valve, filter, and heat exchanger. The contractor needed to find out the cylinder areas and determine if the components were rated for the return flow. Spin-on element threads tend to stretch, making it feel like the element is loose. You can turn the element about 1⁄16 to 1⁄8 of a turn, and it will feel tight. Shortly after running the system, though, the element will start leaking again and can be tightened again. However, the stretched stud the element is attached to could break or the element threads could strip, causing the assembly to blow apart. |