Elevāt has formed a partnership with Microsoft Corp. to help improve the development of IoT (Internet of Things) solutions in the heavy-duty mobile equipment industry.

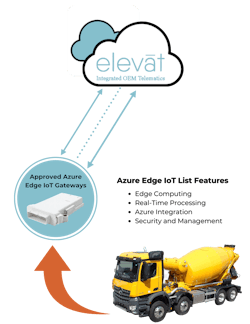

The company will integrate its Elevāt Machine Connect, an IoT platform which monitors machine health, with Microsoft Azure Edge, a software that enables cloud computing to occur at the edge of a network (see sidebar below). This provides faster processing of data collected from solutions like Elevāt’s, allowing more timely decision making to occur so unplanned machine downtime can be minimized.

Adam Livesay, co-founder and CRO of Elevāt, said the company was approached by the Microsoft Azure team because they were interested in expanding into the off-highway space. To date, the technology is mostly used in healthcare, retail and trucking. “We started to look at what it takes to put the Elevāt software inside what is called Azure IoT Edge,” said Livesay in an interview with Power & Motion.

Elevāt was then able to work with a customer to implement the combined solution. Doing so helped demonstrate what could be achieved by bringing the two companies’ technologies together such as improved connectivity between devices on a machine and enhanced analytics capabilities.

Deploying IoT on the Edge Reduces R&D Efforts

According to Livesay, one of the major benefits of the partnership with Microsoft is the ability to ease the development and deployment of IoT solutions – both for Elevat and OEMs.

He explained that Azure IoT Edge is basically a software container which allows companies such as Elevāt to have their code reside on the edge. “Previously, any time someone like Elevāt would work with different hardware suppliers we would have to spend a lot of time deploying and engineering our software to that exact piece of hardware,” he said.

Not only did this require a lot of resources going into a single project, but it could also limit the number of hardware vendors an OEM customer could use. If a different hardware configuration was desired, fewer options may have been possible because the supplier did not have a device available that worked with the IoT and telematics platform.

“An OEM could have three or four different hardware suppliers for the different machines it builds,” said Livesay. “But if they’re all Azure Edge compatible, then the software can stay the same.”

This provides OEMs with greater flexibility because they can use any Azure Edge compliant hardware and be assured their IoT and telematics platform will work as desired. Livesay said this benefits development and scalability for OEMs while also helping to mitigate potential supply chain risks by expanding the network of hardware suppliers with which an equipment manufacturer can choose to work.

Another key benefit is how much Microsoft is investing in security. “There are a lot of enhanced security features on Azure IoT Edge that inherently comes from using an IoT platform that’s deployed on there,” said Livesay.

In addition, he said there are services available with the Microsoft technology which allow users to work with machine learning (ML) and artificial intelligence (AI). “Even if your company is not ready for [AI and ML] yet, the building blocks and foundation are there for when you are ready as a company,” said Livesay. “And those services are just going to continue to get better over time.”

He said it’s likely at some point an OEM or one of its customers will decide to do something in the ML or AI space. Because the technology building blocks are already built into Azure IoT Edge, the heavy equipment manufacturer will not be starting from scratch and therefore investing less time and money into development efforts.

Livesay said the partnership is exciting for Elevāt because of the investments Microsoft is making in edge and cloud technologies as well as IoT. “And it really does help with the different types of hardware options out there now,” he said. “You don’t have to do really large deployment projects. You can find partners that fit the [Azure IoT Edge] criteria and you can start working with them pretty quickly.”

READ MORE: IoT Enables Better Problem Solving in Fluid Power

How Technology Partnerships are Benefitting the Industry

Partnerships like the one between Elevāt and Microsoft have become increasingly more common as a means of accelerating development and scalability of new technologies as well as helping to mitigate some of the risk involved with deploying new products in the market.

Livesay said having major cloud players like Microsoft now looking at how they can create tools to help accelerate IoT services and solutions is a big deal. “Before, companies would have to spend a ton of resources on ‘How do we do this? How do we manage this?’ Now you have this massive giant behind you with Azure that’s helping with that,” he said.

Elevāt’s technology partnership with Microsoft will benefit both OEMs and component suppliers in the off-highway equipment industry, as well as many other industries. As the number of smart, connected components and services increases, the biggest headwinds for component suppliers will be scalability, prototyping and security. Many of them work with various hardware suppliers to implement these smart, connected capabilities. “If those suppliers become Azure compliant, it gives them more options as well,” said Livesay.

He said the partnership also helps to differentiate Elevāt in the market. Many of the companies it works with are already using the Azure cloud for other aspects of their business, such as their IT department, so it can help to ensure compliance across an enterprise. “From a solutions provider perspective, it really helps us because they are investing so much in this [IoT] area,” he said. “They’re investing in the machine learning and AI space, they’re investing heavily into the security space; partnering up with companies that do that helps solution providers like Elevāt.”

From an OEM’s standpoint, there is the ability to work with an IoT provider which can scale up its offering as the manufacturer looks to further improve its own solution. “We’re working with the OEM for its next deployment of service,” said Livesay which can include remote updates, service alerts and more.

“We're looking at utilization, helping them drive non-machine revenue, like aftermarket parts and services; we're helping them with their over-the-air software updates, running their service tools remotely…those are all the things we're focused on. And the more you do [those], the more security and scalability you need,” he said which is possible because of Elevat’s partnership with Microsoft Azure.

When working with an OEM or component supplier, Elevāt will first determine if the customer’s hardware devices have the possibility of becoming Azure compatible, which Livesay said Elevāt can help facilitate, or if they are already compatible.

The latter is what happened with the current OEM Elevāt is working with – the OEM already had Azure Edge approval which made the development time much faster. “All we had to do was put our software on there [the hardware device] and development to deployment time was days instead of weeks or months,” said Livesay.

READ MORE: HydraForce Partners with Tan Delta and Elevāt to Optimize Hydraulic System Maintenance

Specifying some criteria a chosen hardware device must meet not only helps to provide some standardization within a corporation, and even the industry, but will also be necessary as components and machines become smarter. “As you get smarter on the edge and there’s more data processing, you’re going to need more systems like this,” said Livesay.

Deployment of Elevāt’s IoT platform on the Azure Edge software will provide more capabilities for data processing, data batching, analytics and more. He equates it to when companies ran their servers in house then shifted to running the majority of them on the cloud. This allowed companies to move at a faster pace and bring more applications into their fold.

“Now we’re saying you can move the cloud to the edge,” said Livesay. “This is going to be the next wave of IoT.

“[There will be] more connected machines, systems and tools running out [in the market] and having a really good edge strategy with the foundation of Azure IoT Edge, with partners like Elevāt that are working with it, are going to be key to that long-term strategy,” he concluded.