A variety of sensing technologies are available in the market, enabling sensors to detect position, temperature, speed and more. Magnetic sensing is a commonly used option, with Hall effect and magnetoresistive being two of the major types.

Hall effect is likely the most well-known technology as it has been around for a long time and is used in various types of sensors. However, major developments in magnetoresistive technologies over the years have made it a popular option as well.

The most recently developed technology, known as tunnel magnetoresistance (TMR), is gaining ground as an alternative to Hall effect. TMR is comprised of two ferromagnetic layers which are coupled and separated by a very thin non-magnetic, non-conductive insulation layer through which electrons will tunnel, explained Christian Fell, General Manager, Fraba Inc.

It is a robust design with a high level of magnetic sensitivity, leading to improved sensing capabilities which can benefit many applications.

The Benefits of TMR Sensors

According to Fell, use of TMR is increasing in the magnetic sensing market because of the many advantages it can provide versus other technologies. Among them is the fact this technology is less susceptible to temperature fluctuations which helps to ensure its performance in various operating environments.

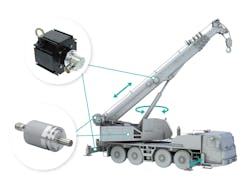

Rotary encoders, for instance, are increasingly using magnetic sensing instead of optical sensing, said Fell due in part to the reduced size and cost of magnetic sensors. Their widescale use in automotive and various other applications have helped to bring down costs while their compact size eases installation and costs as well.

Magnetic sensors are also known to be more rugged and robust, he said, benefiting their use in harsh operating conditions such as off-highway machinery. Inclusion of position sensors on heavy equipment such as excavators and dozers is increasing; while optical sensors could be used for position sensing, they are more susceptible to the shock, vibration, condensation and other elements common in the outdoor environments in which most heavy equipment operates. Therefore, magnetic sensors are a better option.

Fell said Fraba decided early on to use TMR technology for its magnetic based sensors. “We believe in doing our own data processing in the sensor,” he explained. The raw signals provided by TMR sensors enable the company to do this.

By doing the signal conditioning and data processing itself, Fraba gains more flexibility in its sensor designs. It can develop the algorithms necessary to achieve higher resolutions for quicker and more accurate position sensing.

Future Growth Potential for TMR

With TMR technology, sensor manufacturers can create higher performance systems which have a smaller form factor and are more cost efficient, said Fell.

These are important aspects to end use customers. How a sensor will solve a customer’s measurement problem is the most important criteria, but form factor, reliability and cost are also driving factors when choosing a sensor, he noted. TMR makes it easier for sensor manufacturers to meet these criteria.

Allegro Microsystems, a manufacturer of sensor integrated circuits, has invested in TMR technology over the last several years because of the many benefits and application uses it sees. When it acquired Crocus Technology, a developer of TMR sensors, in August 2023, the company said the greater application use and forecasted growth of the TMR market as key reasons for the acquisition.

Automotive and industrial applications are expected to be among the key drivers for this market growth in the coming years, aided in part by the transition to electrification and automation where the company is seeing greater use of TMR technology. The sensing accuracy, temperature resistance and compact size of TMR sensors are just some of the reasons they are being used in these applications.

Automation in particular requires a high level of accuracy to ensure vehicles and machines move as desired and in a safe manner. The better a sensor is at determining position, sensing objects or providing other necessary data, the greater the accuracy and safety which will become increasingly more important as higher levels of automation are achieved.

Fell concluded that TMR is still a fairly new technology. As such, further technological developments are likely to occur in the coming years which will improve its capabilities even more. This will help to bring down the cost of TMR sensors as well as enable an even broader range of applications in which they can be used.