Governments are trying to combat climate change with subsidies for producing more electric vehicles, but the main reason for the accelerating electrification of transportation and industrial equipment is economic pressure. Electricity, as one common energy platform, is efficient, and the switch to electric-powered engines reduces the cost of ownership.

Moreover, the rapid advancements in technology are a driving factor behind the transition. High-performance and fast-charging batteries are not only decreasing range anxiety but also improving the reliability of the vehicle and overall user experience, making the electric platform more attractive to consumers.

While the government's promotion of electric vehicles on the premise of combating climate change supports electric vehicle (EV) sales and battery manufacturing, the true reasons behind the switch are more complex. The considerations of economy, technology, and resource availability are more impactful in driving the change.

When assessing the carbon dioxide (CO2) emissions of electric versus internal combustion engine (ICE) vehicles, it's crucial to consider the source of the local electricity generation. Regions with a larger share of renewables in their energy mix stand to benefit more from an increase in electric cars, as these will significantly reduce overall emissions. Conversely, in regions where electricity predominantly comes from coal, an uptick in electric power generation to fuel these vehicles may inadvertently lead to higher emissions.

A large-scale reduction of emissions from both personal and commercial transportation isn't solely contingent on the number of electric vehicles on the road. Rather, it requires a comprehensive approach that includes improving the efficiency and utilization of commercial transport, promoting shared ownership and automation of passenger vehicles, enhancing public mass transit systems, and ultimately encouraging shorter, less frequent travel.

Electrification is a fundamental component of the energy transition from fossil fuels to cleaner and renewable energy sources. This trend is enduring because it is supported not only by political incentives aimed at combating climate change, but also by compelling economic factors, advancements in technology, and looming oil scarcity.

Economic Drivers for Electrification of Commercial Vehicles

Economic drivers are easier to track with commercial transport, and companies are much better at tracking data and ROI calculations than individuals. Commercial electric trucks provide a good example of this.

Off-highway industrial vehicles, such as forklifts, have been increasing the share of electric lift trucks for a few decades now, reaching 72% in the US in 2021, according to the Industrial Truck Association (ITA). Electric lift trucks are cleaner, less noisy, and more economical than propane- or diesel-powered forklifts, especially with the current high fuel prices.

Commercialization of lithium battery technology further accelerated the electrification trend in materials handling equipment. Lithium batteries enable the electrification of transport and industrial equipment, where traditional lead-acid batteries could not do the job: forklifts in power-hungry applications such as paper, lumber, metals, beverages, etc.; cranes and excavators in construction and mining; railway engines; boats; and even airplanes.

READ MORE: Construction Equipment Digs Deeper into Electrification

Companies see real savings and higher operational efficiency with the adoption of lithium batteries, and electrification is driven by the following key factors: better equipment performance, the lower total cost of ownership, the infinitely more advanced data capabilities provided by monitoring systems, and the ability to “communicate” with the battery. Real-time data collection, remote monitoring, predictive maintenance, troubleshooting, optimized charging, etc., are all easy to achieve with lithium batteries.

Lithium allows for regenerative braking, where braking energy is converted to recharge the battery. In lead-acid batteries, this was very much limited, when it was even possible.

The safety of operations is also improved. In the case of material handling equipment, single-battery operation and zero daily maintenance have radically reduced the number of battery-related accidents and potential costs for business.

Another practical reason for the electrification of commercial fleets is lithium-ion (Li-ion) vehicle-to-grid capabilities. When connected to the electric power grid for charging, a Li-ion-powered vehicle can serve as a “vehicle-to-grid” node used for “power shaving” the electric load on a particular site. This approach can further decrease energy costs and contribute to the resiliency of the electric network and the effective use of renewable solar and wind energy.

Incentive Programs for Commercial Fleet Electrification

Federal, state, and utility-led programs have been offering incentives for companies to switch to electric industrial equipment for many years now, but it is hard to say whether they were key factors in electrification. Konecranes technology director Anders Nilsson told the publication Forkliftaction that funding or taxation relief is often available in many countries but customers may not be aware.

Before planning a direct ban on the sale of new large spark ignition (LSE) forklifts starting in 2026, the California Air Resources Board (CARB) offered to finance the purchase of electric forklifts through its Clean Off-Road Equipment (CORE) incentive voucher program, which had a budget of $125 million. The Low Carbon Fuel Standard (LCFS) program, also run by CARB, allows companies to generate carbon-emission offset credits, which can be sold on the open market, for using electric equipment instead of propane- or diesel-powered versions.

LCFS programs are also available in Oregon, Washington, and British Columbia (Canada). South California Edison’s “Charge Ready Transport” program was launched in 2020 to provide financing for the charging infrastructure required by commercial buyers of new electric equipment.

“For the customers of OneCharge lithium batteries, the government incentives are nice to have, but the key reasons to switch to lithium forklift batteries have always been the ROI, improved efficiency, safety, and environmental impact of this new technology,” says Tim Karimov, President of OneCharge.

For commercial vehicles, the switch to electric is driven by return on investment (ROI) and triggered by advanced lithium batteries. Government incentive programs and the prospect of achieving their environmental strategy goals help company executives make a decision, but these are not the decisive factors.

The Impact of EVs on GHG Emissions

Transportation is the biggest source of greenhouse gas (GHG) emissions in the U.S., accounting for 39% of total emissions. Private passenger vehicles are responsible for over 58% of the U.S.’s transport emissions, and for 15% of all GHG emissions globally, making it the primary target of efforts to reduce emissions.

Passenger EVs are often presented as the solution mainly because they produce zero tailpipe emissions (no exhaust gases). However, it is important to evaluate the emissions generated from car and battery manufacturing, and the emissions from fuel and electricity production.

From EV Manufacturing to Recycling: Emissions at Each Stage

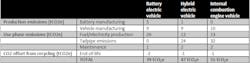

The below chart provides an overview of the 2021 life cycle emissions of medium-sized electric, hybrid, and ICE vehicles in each stage of their life cycles, using metric tons of CO2 equivalent (tCO2e) from a report by Kearney Consulting. These numbers are based on a car driven for 16 years and 150,000 miles.

Electricity production is by far the most emission-intensive stage in a battery-electric vehicle's (BEV) life cycle. Overall, lower emissions from EVs in these calculations are based on a global average of 39% fossil-free electricity. However, each EV uses locally generated electric power.

California gets over 50% of its electricity from non-fossil sources, and more EVs on the road means fewer overall emissions. But this benefit does not start on day one — calculations show that in Germany, an EV becomes greener only after 62,000 miles.

On the other hand, if Arkansas residents replace gas-powered cars with electric ones, the increased power demand will increase overall emissions, because almost 70% of Arkansas electricity comes from burning natural gas and coal.

What makes EVs even less environmentally friendly in Arkansas is that the lion’s share of electricity generation comes from coal, and coal generates about twice the amount of CO2 as natural gas. This is not to say that natural gas is a solution to a GHG problem, even though its share in the U.S. has grown dramatically over the last decade. During natural gas extraction, methane — which is a greenhouse gas 34 times stronger than CO2 over 100 years — leaks into the atmosphere, thus in a short time, combusted methane is a more significant greenhouse gas than carbon dioxide.

Incentives, Rebates, and Government Support of EV Sales

Incentives and rebates do move the needle with EV sales, unlike what we see with industrial vehicles and equipment, where businesses are switching to electric equipment based on positive ROI. Research by RMI predicts a steeper rate of adoption of all types of electric vehicles with the money from the Inflation Reduction Act (IRA).

There are complicated and much-debated criteria for how to distribute the money, and the manufacturers of passenger EVs are actively spending on lobbyists: Rivian has retained the Klein/Johnson Group, whose co-founders are former aides to Senate Majority Leader Chuck Schumer (D) and Sen. John Cornyn, a top Republican, and Lucid Motors has brought on the Monument Advocacy group.

The Future of Transportation is Electric

There is little doubt that the future of transportation is electric: electric engines and powertrains are more efficient, cheaper to build and maintain, and more reliable. Electric networks that include multiple generation sources and energy storage units will bring additional economies of scale, redistributing energy and managing demand response with highly effective artificial intelligence (AI) programs.

READ MORE: The Current State of Battery Technology

Furthermore, the impending deficit of oil and the volatility of oil prices are significant incentives for the shift to electric platforms. Electric-based systems, unlike fossil fuel versions, can be powered by a wide array of renewable energy sources, thus providing a sustainable and long-term solution to the energy needs of the world.

Electric vehicles are part of a solution to fight climate change, even though emissions will go down only as electricity generation transitions to low-carbon sources: hydro, nuclear, wind, solar, geothermal, and others. In the meantime, a large-scale decrease in emissions from both cargo and passenger transportation can be achieved through decreasing the volume of transportation and improving its efficiency.

There are reasons to believe this is possible: miniaturization and advanced materials development are reducing the weight of goods and shipments. Real-time optimization of the supply chain with the help of AI can also provide gains in efficiency and a higher utilization rate, resulting in fewer vehicles on the road.

Urban planning now includes mass public transportation to reduce the demand for passenger cars. Remote and hybrid work and the adoption of shared and driverless cars are also reducing the demand for new cars. The advancement in electronics and labor shortages are pushing companies to adopt such solutions.

Electrification does not immediately lead to drastically lower emissions. But both transport and industrial equipment will continue to adopt electric motive power. We see a diverse set of stimuli, and we can predict a long-term and sustainable trend for electrification.

This article was written and contributed by Maxim Khabur, director of marketing at OneCharge, a U.S. manufacturer of lithium industrial batteries, and chairman of the Advanced Energy Council, representing a group of 20-plus companies which produce and support advanced energy technologies and are members of MHI.org (Materials Handling Industry Association).