Solid-state batteries are viewed as a beneficial power source for electric vehicles because they can overcome some of the challenges associated with the lithium-ion batteries currently used in most all-electric and plug-in hybrid vehicles.

Extended range, longer lasting charges and improved safety are some of the benefits associated with solid-state battery technology. These will aid the continued uptake of electric vehicles (EV) by overcoming some of the concerns consumers currently have with EVs such as range anxiety and charge times.

However, there are some technological challenges which must be overcome to make use of solid-state batteries more widespread within the EV market.

Dr. Rashid Farahati, Ph.D., Director, Corporate Competency Center Americas, Schaeffler, is leading the company’s development of next-generation solid-state batteries. Like many other companies developing this type of battery, Schaeffler foresees potential in the technology addressing many of the concerns associated with current EV batteries.

Dr. Farahti spoke with Power & Motion about what makes solid-state battery technology different, the challenges which need to be overcome and when these batteries may enter the market.

What Makes Solid-State Batteries Different?

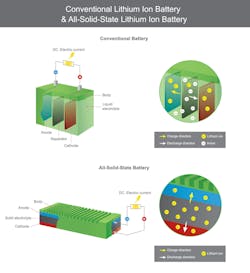

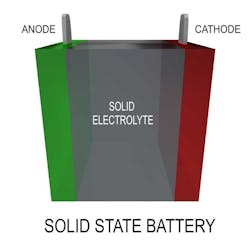

As their name indicates, solid-state batteries use solid electrolytes whereas liquid or polymer gel electrolytes are used in the majority of EV batteries in the market today.

Replacing the liquid electrolytes with solid ones brings about many benefits, said Dr. Farahti. The number one benefit is improved safety. “The liquid electrolyte is organic [which] means it is flammable,” he said.

In a battery, oxygen is generated because of the reaction which takes place within it and there will sometimes be a spark. The liquid electrolytes can act as a fuel source, and when combined with the oxygen and spark cause fires to occur, he explained. However, if you remove that fuel source – i.e., the liquid electrolytes – even if there is oxygen or a spark, the risk of fire is eliminated.

“That would address one of the biggest concerns with electric vehicles,” said Dr. Farahti.

He went on to say that solid-state batteries address three of the four major issues currently hindering greater adoption of EVs:

- safety,

- range anxiety, and

- fast charging.

Using solid instead of liquid electrolytes improves safety by removing the risk of fire. It can also help overcome the range anxiety issues associated with conventional EV batteries by enabling different anode technology to be utilized.

Currently, graphite anodes are used in liquid electrolyte-based batteries. These can be replaced with metallic lithium anodes when using solid electrolytes which offers increased energy density. In addition, Dr. Farahti said these anodes are much thinner and require less space which helps to create a more compact and lightweight battery – when combined with the increased energy density possible, driving range can be extended with solid-state batteries.

At the moment, the average EV can drive about 300 mi. between charges whereas gasoline-based vehicles provide a range of 500 mi. he said. But many car manufacturers are targeting 900-1,000 mi. for future EVs equipped with solid-state batteries. “That is only feasible because you are making the battery pack lighter [in weight],” he said.

Charging time can be improved with solid-state batteries as well because they can hold more energy. “By replacing lithium, we have the potential to reduce charging time to 10 minutes,” he said. Today’s lithium-ion powered EVs can take close to an hour or more to recharge. Getting charge times closer to that of refueling a traditional internal combustion engine powered vehicle could greatly help to increase the uptake of EVs.

The fourth issue with EVs is cost, which currently solid-state batteries are not able to overcome. Initially these batteries will have a higher cost, but as volume picks up they will come down as they have for other batteries. “If you look at existing batteries [over] the last 10 years, the cost dropped significantly,” said Dr. Farahti. “Solid state is going to have the same evolution; at the beginning it is going to be costly, but by increasing the volume the price will drop.”

Technological Challenges Need to be Addressed

Although there are many benefits offered by solid-state batteries, challenges exist with the technology which are preventing it from being widely used in the market at the moment.

The number one challenge according to Dr. Farahti is related to how ions move through the electrolyte. Use of liquid electrolytes makes it easy for ions to move between the anode and cathode during charge and discharge states.

However, movement between the electrodes (the anode and cathode) can be difficult with solid electrolytes. “Imagine there are two surfaces which there is a barrier between…the ion has to jump [over the barrier] to get from one surface to the other,” he explained.

To overcome this, it is necessary to design a surface interface in such a way that ions can penetrate through the surface instead of jumping over it.

Another challenge is related to charging and discharging of the battery. During these states the surface interface expands and contracts which can cause cracks and initiate some resistance because the ions cannot pass through them, negatively impacting battery cycle life – the number of times it can be charged and discharged before losing performance.

Applying external pressure in the battery, called stack pressure, can help overcome this issue.

“Right now, solid state requires high stack pressure…about 5 megapascal (MPa) which is not feasible to put in a vehicle economically,” said Dr. Farahti. “We have to reduce this pressure to 1 MPa. If we can reach 1 MPa stack pressure, we can say it is a good design.”

He said this is an area in which many companies are focusing development efforts, and some have had success reaching the lower stack pressure at small scale, including Schaeffler. But doing so on a larger scale remains a challenge.

The process used for achieving lower stack pressure in a laboratory setting is too expensive for mass production purposes, he said. “You [must] have higher volume to bring the price down and we need to bring the price down to put it in mass production,” which creates a quandary for the industry.

It could be possible to take a Tesla-like approach where the technology is first introduced for high-performance, niche market applications which is low volume and as manufacturing gradually increases the price point will come down.

READ MORE: New Research Looks to Improve Safety of Battery Technology

When will Solid-State Batteries be Available?

There are differing opinions on when solid-state batteries may be available within the market. Dr. Farahti said his own opinion is that next-generation battery technology is necessary to ensure continued uptake of EVs.

While electric vehicles have reached a point where consumers are interested in them, they are not quite as popular as they could be due to the four key issues associated with them – cost, charging, safety and range.

Rapid development of liquid electrolyte-based batteries over the past decade helped uptake of EVs in recent years. Improvements continue to be made for these battery technologies, but they are on a smaller scale at this point. “They are trying to get 1or 2% improvement, not 10 or 20%,” he said. “So, we need some kind of evolution of the battery,” to achieve higher levels of improvement.

Laboratory work conducted by Schaeffler and other companies has proved solid-state batteries work and solve many of the issues associated with current technology, but scale remains the challenge to overcome.

Dr. Farahti said the company believes its years of manufacturing expertise can address this challenge. Its advanced manufacturing capabilities and coating system which could be used for the surface interface of a solid-state battery are ways he said it may be possible to scale up production of these batteries.

He believes solid-state batteries are coming, it is just a question of timing. “The more demand we get from customers, the sooner [this technology] is going to come to the market,” he said. But a lot of investment and R&D effort is needed to do so.

In general, though, he expects to see solid-state batteries in low-volume production by the end of the decade. Several EV manufacturers have made similar predictions as well, with some saying they plan to bring solid-state battery powered vehicles to market as early as 2027.

READ MORE: Electric Vehicle Development to Grow Over Next Decade