bauma 2022, one of the largest international trade shows for the construction and mining industries, is set to take place October 24-30, 2022. Held once every 3 years — alternating with CONEXPO-CON/AGG and IFPE in the U.S. and INTERMAT in Paris — the event highlights the latest components and equipment in construction and mining.

Like other industries, electrification of construction and mining equipment is becoming more prevalent. This is due not only to machine owners wanting to use lower emissions equipment but also governmental regulations. Equipment and component manufacturers have been working on electrified solutions for several years now, but the technology has finally gotten to the point at which it is viable in real-world applications.

READ MORE: bauma 2022 to Highlight Key Technology Trends for Construction and Mining Equipment

Several OEMs have already introduced electric-powered machines to the market, and more prototypes continue to be unveiled. Currently, the majority of the battery-electric construction equipment available or under development is compact; this is due to the smaller battery size required and reduced charging times. But larger machine options, including hybrids, are in the works as well.

Mining has used electric drive for some time. And underground mining equipment has been powered by batteries for several years now as the elimination of emissions greatly benefits worker safety and reduces the need for expensive ventilation systems. However, these machines are much larger and many mine sites have their own electricity which has made the switch to electrification easier.

Electrification of construction equipment has its challenges due to the varying size and duty cycles of the equipment and the charging infrastructure needed. But as technology has evolved, electric-powered construction equipment is becoming a reality.

During a recent interview with Power & Motion, Kimmo Rauma, Vice President of Danfoss' Editron division, said electrification is now moving at a fast pace in construction equipment and other applications. He said bauma 2022 will have the largest collection of electric machines ever on display due to the significant growth taking place in electrification.

Several manufacturers have started to announce the electrification solutions they plan to show at bauma, including Danfoss which said in a pre-show press release that electrification will be among the key technology areas it showcases in conjunction with solutions for autonomy, digitalization and connectivity.

Briggs & Stratton Displaying New Battery Technology

In addition to its latest engines, Briggs & Statton will exhibit the newest battery solutions in its lineup. The company said in its pre-show press release the new battery technologies it plans to introduce at bauma will benefit those in the rental and construction industries.

Among the technologies on display will be the Vanguard Commercial Lithium-Ion Battery pack which is available in the North American and European markets. It is available in 5 and 10 kWh power ranges, and has already been integrated into various construction applications as well as those in the defense and agricultural industries.

In July, the company announced an expansion to its battery portfolio with the launch of its Vanguard 7 kWh Diecast Commercial Battery. This battery increases the amount of applications in which Briggs & Stratton's technology can be used.

HAWE Introduces New PowerBox for Electrification

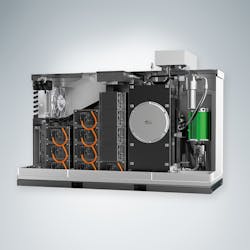

HAWE Hydraulik has introduced a new PowerBox to aid electrification of mobile machines which will be displayed at bauma 2022. The PowerBox contains battery packs, a new Motor Pump Unit, a Power Distribution Unit, a charger and hydraulic components.

All of the components are contained in a single for ease of installation and it can be adapted to meet the specific requirement's of an OEM's machine and application. The PowerBox comes full charged and features a plug-in system for the battery packs to simplify runtime management said HAWE in its press release announcing the launch of the PowerBox. Once the batteries are fully discharged, they can be quickly swapped out for charged batteries which helps to minimize downtime for machine owners.

The new PowerBox has been put to use in loading cranes (see image at top of article illustrating use in this application) but can be used in a variety of other applications as well.

In addition to the new PowerBox, HAWE plans to exhibit its in-house developed battery packs designed to power off-highway equipment or driving a machine's working hydraulics. It will also show its ROVO robotic platform, an all-electric track-mounted drive system which can easily traverse off-highway work environments. HAWE will also show its technology for decentralized drives for hydraulic systems in electric-powered machines.

Moog Partners with Komatsu on Electric Wheel Loader

Moog Inc. recently collaborated with equipment manufacturer Komatsu on the development of a fully-electric compact wheel loader. The machine is battery powered, autonomous ready and will be on display at bauma 2022.

The electric compact wheel loader features Moog's intelligent machine electrification system which includes:

- electric traction motor,

- lift, tilt and steering electric cylinders,

- power electronics,

- system control computer,

- battery and battery management system.

Integrated software provides control for the electrification system while its electric actuators and motors provide necessary machine movements. The system is designed to provide seamless integration into machines to help ease development and time to market for OEM customers.

"Our focus is accelerating electrification, automation, and connectivity by enabling the world’s safest, most sustainable, and most productive machines," said Joe Alfieri, vice president and general manager for Moog’s construction business unit, in the company's press release announcing the collaboration. "Our cooperation with Komatsu shows that industry leaders in the construction industry are ready for zero-emission machines and we are thrilled to collaborate with them to enable their journey with our production-ready electric, connected and automation systems."

After bauma, Komatsu and Moog intend to jointly test the electric wheel loader and are looking to prove the machine can provide improved efficiency, comfort and other benefits through electrification.

"The machine, built together with Moog, combines the strengths of both companies, and was finalized within a short period of time. We expect the joint testing will show the advantages of a fully electric machine and will prove collaboration is beneficial for both sides," said Seiichi Fuchita, Chief Technology Officer and President of Development Division, Komatsu, in Moog's press release.

Technical Services Introducing High-Voltage Thermal Management Solution

Thermal management and airflow technology developer Technical Services (UK) Ltd plans to introduce a thermal management system for electric-, hybrid- and fuel cell-powered vehicles at bauma 2022. Use of high-voltage cooling components in the system will benefit electric vehicles operating at higher power levels by ensuring they do not overheat or suffer from other thermal issues.

The system is supplied as an off-the-shelf kit containing pumps, heat exchangers, fans and connecting parts typically used within an electric vehicle's cooling loop. This provides OEMs an all-in-one solution to ensure optimal thermal management which is vital in electric vehicles due the heat which can be generated by batteries and other electronic components.

Technical Services can also customize the thermal management system to meet specific application requirements.

Parker Focusing on a Greener Future

Parker Hannifin's bauma exhibit will focus on the theme of "Projecting and engineering a greener future." In addition to exhibiting various technologies related to this theme the company also plans to host expert topics during the show on subjects such as electrification, IoT and more.

The company states in a pre-show press release it will address four key topics through its exhibit and technology talks which highlight the future of the construction and mining industries:

- Driving the energy evolution through alternative fuels and hydrogen

- Achieving carbon neutrality via electrification and carbon-free construction methods

- Implementing digitalization, IoT 4.0, and automation to improve reliability, safety, and productivity

- Enhancing reliability and productivity, particularly in harsh conditions like mining and construction.

Among the new technologies Parker plans to exhibit is the SensoControl SCP04 pressure sensor for hydrogen applications. According to the company, the new pressure sensor meets the chemical and physical requirements of the entire hydrogen lifecycle and its different threads match the need of various system connectors. The sensor features high-pressure resistance and is capable of detecting pressures from 4-1,000 bar.

"We see the expo as the perfect place to unveil our latest engineering breakthroughs for a greener future, helping the industry to address the twin challenges of increased productivity and profitable sustainability. We will be exhibiting reliable, optimized solutions, which enable vehicle electrification and digitalization, reduce carbon emissions, and transition diesel-powered platforms to alternative fuels like biodiesel or hydrogen – all while performing reliably and safely in some of the harshest environmental conditions," said Joachim Guhe, Parker’s President for Europe, the Middle East and Africa (EMEA), in the company's pre-show press release.

Delta-Q Technologies Introducing High Power Chargers

Battery charging solution provider Delta-Q Technologies will show its range of chargers for construction equipment at bauma. Among these will be the company's new higher powered options.

Its new XV3300 three-in-one charging solution delivering up to 22 kW will be exhibited during the show. The XV3300 features a high-performance 3.3 kW charger, a 500W DC-DC converter and an EV charging station interface compliant with SAE J1772 (level 1 and 2) and IEC 61851 (mode 2 and 3). This charging interface enables use with standard electric vehicle AC charging stations in North America and Europe.

Delta-Q said in its pre-show press release that the XV3300 was designed to meet the high-power demands and fast-charging needs of heavy-duty vehicles like construction equipment. The compact size of the charger eases installation and will benefit OEMs developing electric-powered machines.

At bauma, Delta-Q will also exhibit its ICL1500 modular charger capable of delivering up to 7.5 kW.