While mechanical bearing guidance is suitable for most motion applications, it has many drawbacks. In applications where lifetime, minimal vibrations, optimal precision, repeatability, or geometric performance are essential, air bearings can provide superior performance and deserve a closer look.

Air bearings and air bearing motion stages utilize a cushion of air to eliminate mechanical contact, thereby effectively mitigating common problems associated with traditional bearings such as friction, wear, vibration, hysteresis effects, and particle generation.

These factors serve as key indicators that air bearing stages may be the ideal choice for high precision, 24/7 test automation and metrology applications.

How Air Bearings Achieve Exceptional Precision

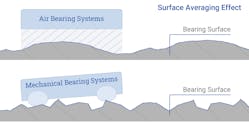

Air bearing surfaces are usually hard coated and meticulously ground to achieve exceptional tolerances. High bearing stiffness is achieved by frictionless magnetic or vacuum preloading. The surface averaging effect helps to provide significantly better geometric performance, such as straightness and flatness because the large area of the bearing together with the precision ground surfaces can deal much better with small imperfections than ball bearings or roller bearings (see Figure 2 below).

The effect can be compared to the difference between a hover craft and a conventional truck riding over a pot-hole-covered highway. That averaging effect is also comparable to the smoothness of a magnetic levitation train versus a conventional train running on steel wheels.

With the absence of wear, and no need for lubrication and maintenance, air bearings offer considerable benefits in high-speed motion applications and precise positioning, particularly in high throughput 24/7 automation scenarios that are demanding high uptime and reliability.

Why Air Bearings Benefit Precision Motion and Positioning Applications

There are eight key advantages air bearings can provide over mechanical bearings when used in applications requiring precision motion and positioning.

1. Virtually Unlimited Lifetime, Maintenance-Free, Clean Room Compatible.

Since air bearings work without mechanical contact between components, they do not deteriorate and thus do not require periodic inspections, maintenance, or relubrication cycles. Also, unlike with cross-roller bearings, there is no risk of cage migration, especially when small repetitive motion cycles are executed.

Due to the absence of friction and lubricants, these systems also fulfill the requirements for clean room applications.

READ MORE: Robots Improve Cleanliness in Manufacturing Operations

2. Motion with Excellent Geometric Performance and Extremely Small Straightness, Flatness and Eccentricity Errors

Air bearings provide high accuracy, owing to the high precision manufacturing process of their components. Due to the surface averaging effect, linear air bearings feature exceptionally flat and straight travel (0.75µm over 500 mm) with minimal roll, pitch, and yaw errors (10µrad), and rotary air bearings are also superior in terms of eccentricity, wobble and tip/tilt. This makes them highly suitable for manufacturing and measurement processes such as optical inspection, providing excellent repeatability of the same procedure.

This exceptional precision matters for advanced manufacturing processes where every nanometer counts: for example, modern semiconductors are produced with line widths of single-digit nanometers, and even mechanical components in the latest generation of automotive engines can require submicron precision.

3. True-Planar Multi-Axis Motion

Planar XY stages and XY-theta stages cannot be designed with traditional mechanical bearings. Here, individual axes are usually stacked on top of another. In some instances, XY stages are combined into a single assembly and falsely called planar stages, however the X and Y axis do not use the same reference plane.

The approach of building a multi-axis motion system by stacking individual axes is simple but has several drawbacks. As the upper axis moves to the extremes, it will generate torque loads on the lower axis, leading to geometric errors. In air bearing designs, fully planar XY and XY-Theta positioning systems are feasible, where all degrees of freedom reference to the same base plane and are fully supported over the full travel range.

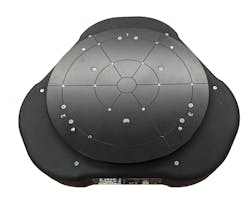

The A-322 XY-Theta stage for example (see Figure 3 above) uses one common plane for both X and Y motion, and a flexure joint on the cross axis even allows for 1 degree of rotation around Z, a great advantage in applications where small alignment errors need to be corrected.

A special gantry control algorithm with a separate Theta-Z control loop in the motion controller takes full advantage of that feature. The function is explained in the below video.

4. Motion with Highly Constant Velocity, Vibration-Free and Very High Dynamic Range

The fluid film in air bearings can readily accommodate high velocity, and some air bearings can even improve efficiency at high speed, due to aerodynamic lift effects. Certain processes and experiments, such as semiconductor wafer scanning, 3D tomography, and inertial sensor testing, demand constant motion at precisely controlled speeds, where mechanical bearing rumble would introduce unwanted errors.

In these instances, air bearing systems are the most appropriate solution to provide the necessary continuous motion at minimum speed fluctuations, and they also last longer than mechanical bearings.

5. Long Travel Ranges are Feasible

Air bearings are not limited to short travel ranges, in contrast to another well-known frictionless positioning technology, often used in nanopositioning applications: Piezo flexure guided mechanisms can provide sub-nanometer precision, high scanning speeds and share many of the advantages of air bearings, however their travel ranges are limited to micrometer and the lower millimeter range.

With air bearings, motion ranges beyond 1 m are easily achievable and all the advantages of smaller air bearings are carried over.

6. High Accuracy, Frictionless Motion

In linear motion applications, precise positioning of a moving carriage within a few nanometers is achievable by using a non-contact, direct-drive motor and high-resolution optical encoder in combination with an air bearing. For rotational applications, angular resolutions to tenths of arc-seconds are achievable. Here, slotless torque motors are used as the driving force.

Air bearings are often preferred in many inspection, metrology, and manufacturing applications due to their minimal hysteresis effect or reversal error, which arises from a lack of mechanical contact and friction. The elimination of friction makes it possible to minimize hysteresis and improve repeatability and accuracy significantly.

READ MORE: Closed-loop electrohydraulics upgrades bearing tester

Another technology to be considered in precision positioning, with similar performance to air bearings, is called magnetic levitation. Here, magnetic fields replace the function of air as a supporting medium, but control electronics are significantly more complex because all 6 degrees of freedom have to be monitored and controlled all the time.

7. Rotary Motion with Minimal Eccentricity and Wobble

Rotary air bearings are highly effective in providing precise rotary motion due to their high stiffness and the aforementioned surface averaging effect. In air bearing rotary stages, wobble or tilt errors typically occur within the range of 0.1 to 1 arc-second—significantly smaller than with mechanical bearing-based rotary stages.

8. Cost-Efficiency

Air bearing mechanisms can also use air pressure to provide actuation in addition to guidance. This design eliminates additional electric motors, reducing complexity, size, and cost.

In general, absence of wear and tear and the need for maintenance is a great advantage, reducing operating cost and improving ROI (return on investment). This may be the most important factor when designing high-throughput automation equipment with 24/7 operation and stringent uptime requirements for years to come.

Summary

Overall, air bearings offer a number of advantages over traditional bearings. They are more precise, accurate, and durable. They also operate more quietly and produce less vibration. Air bearings are environmentally friendly and cost effective.

Finally, they can be designed to meet a wide variety of requirements in various industries, including semiconductor manufacturing, precision machining, metrology, aerospace, and scientific research.

This article was written and contributed by Stefan Vorndran, Vice President, Marketing, PI (Physik Instrumente) LP.